Tools for Designers:

BOM Compare Tool

Sierra Circuits' BOM Compare Tool is the first web application that enables you to compare two PCB BOMs and identify differences between them within no time. You just have to upload bills of materials and map the columns, the tool quickly displays newly added, deleted, and modified data.

Try This New ToolSierra Circuits’ BOM Compare Tool is the first web application that enables you to compare two PCB BOMs and identify differences between them within no time. You just have to upload bills of materials and map the columns, the tool quickly displays newly added, deleted, and modified data.

How this BOM Compare Tool can help you

PCB designs generally undergo multiple iterations during the design phase. Hence, you have to submit a new or revised bill of materials to your manufacturer. Before this, you need to compare and validate the BOM data to avoid miscommunication and expensive delays.

Manually comparing the details such as component names, quantities, and MPNs is a time-consuming and cumbersome process.

To help you overcome this challenge, Sierra Circuits has introduced the BOM Compare Tool. This web app can quickly identify the changes in the BOM, and validate the data. You can share the updated BOM with the quoting team to proceed with the ordering process.

Key features of the BOM Compare Tool

- Accepts your BOM files in multiple formats including CSV, xls, and xlsx

- Automatically maps 4 columns (item number, MPN, quantity, and reference designator) of your component list files

- Displays results using color codes:

- Green: Added data

- Red: Deleted data

- Blue: Modified data

- Easily exports the comparison data to a spreadsheet

How to get started with the BOM Compare Tool

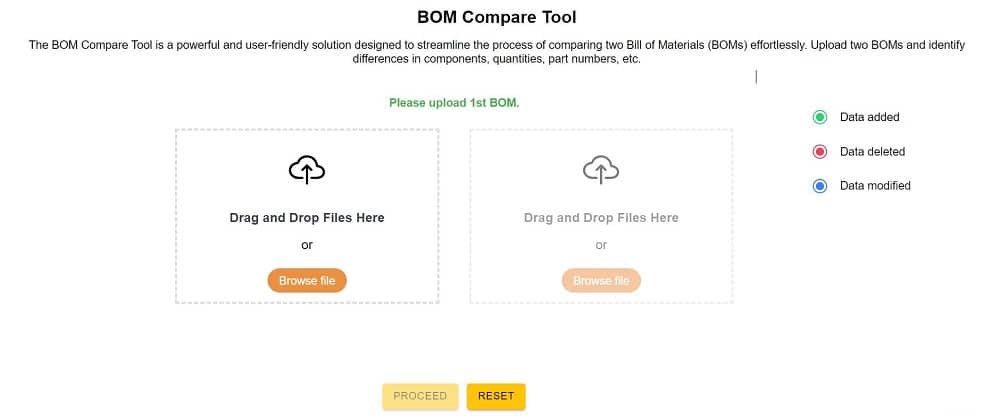

Step 1: Upload your BOMs

Upload your first BOM on the left as shown above and the second one on the right. The color codes on the extreme right differentiate among newly added, deleted, and modified data. Newly added in green, deleted in red, and modified in blue.

After uploading the bill of materials files, click on Proceed.

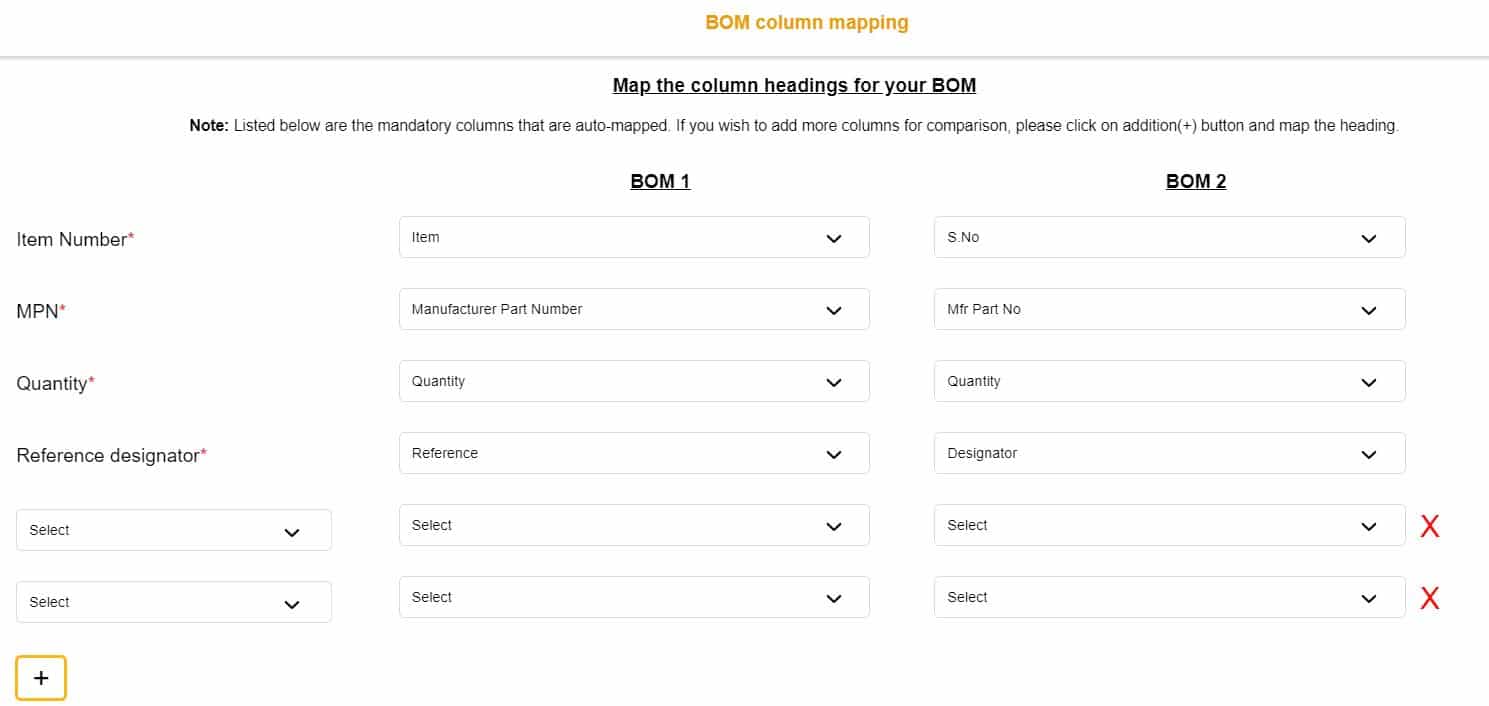

Step 2: Map the BOM columns

The tool automatically maps item number, MPN, quantity, and reference designator fields. If you’d like to compare more fields you can add them by clicking on the “+” button. Apart from the default parameters, you can include up to 6 fields.

To delete the added columns, you can click on the respective “X” buttons.

Hit Compare to view the results.

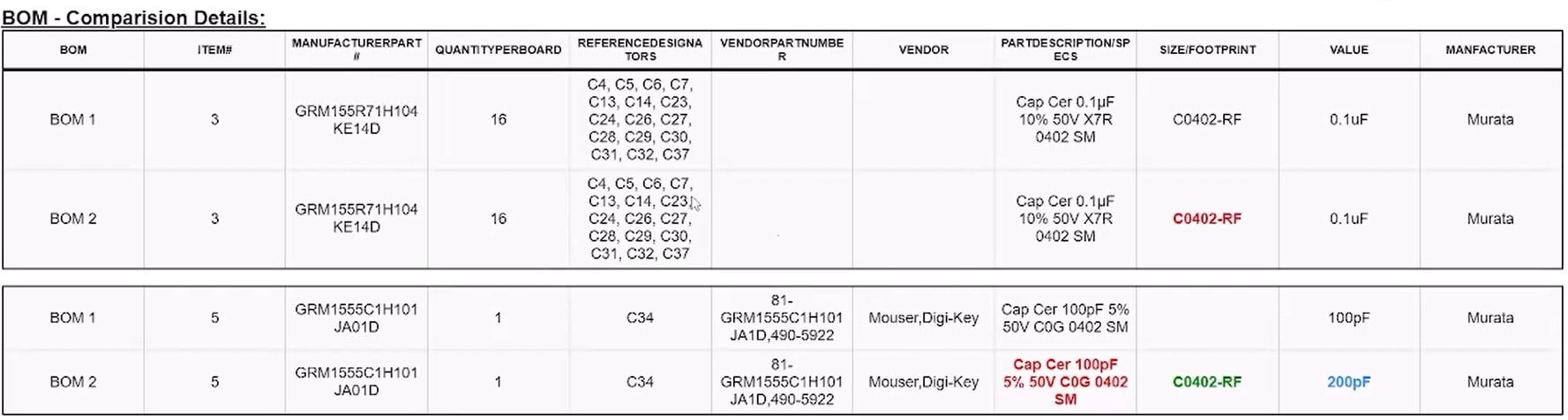

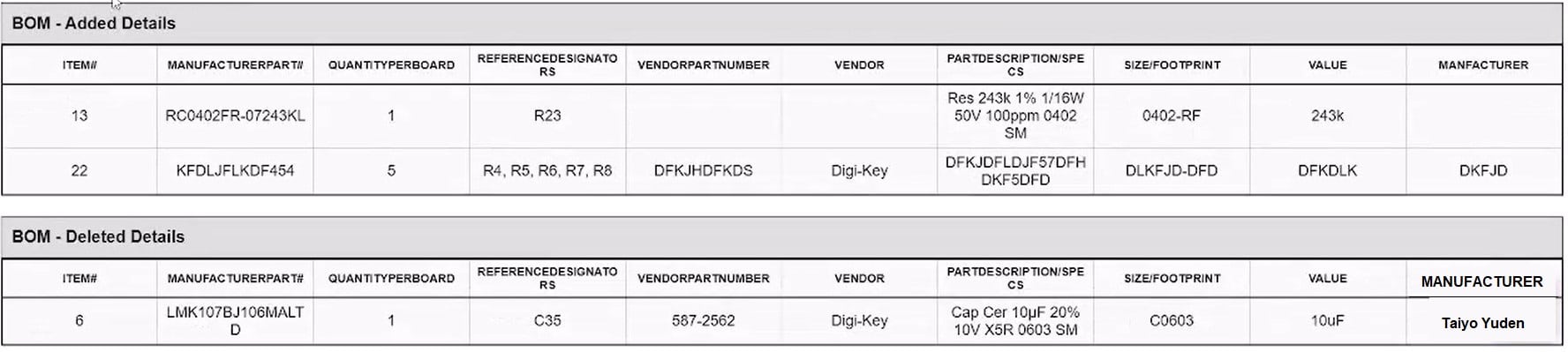

Step 3: Check the comparison output

The comparison results will have 3 sections:

- BOM- Comparison Details: This section displays the modified data in blue.

- BOM- Added Details: Newly added line items will be displayed in green color.

- BOM- Deleted Details: Discarded components will be shown in red color.

You can also download the output data by clicking on the Export to Excel button at the top right corner.

Sierra Circuits’ BOM Compare Tool is a comprehensive solution to quickly analyze and contrast two bills of materials. This user-friendly interface highlights the addition, deletion, and modifications in the uploaded BOMs. Visit our designer’s tools page to explore all our advanced PCB design tools.

Sierra Circuits has developed easy-to-use tools for PCB designers and electrical engineers at every stage of circuit board development.

Fabrication, Procurement, & Assembly. PCBs fully assembled in as fast as 5 days.

- Bundled together in an entirely-online process

- Reviewed and tested by Engineers

- DFA & DFM Checks on every order

- Shipped from Silicon Valley in as fast as 5 days

Fabrication. Procurement & Assembly optional. Flexible and transparent for advanced creators.

- Rigid PCBs, built to IPC-6012 Class 2 Specs

- 2 mil (0.002″) trace / space

- DFM Checks on every order

- 24-hour turn-times available

Complex technology, with a dedicated CAM Engineer. Stack-up assistance included.

- Complex PCB requirements

- Mil-Spec & Class 3 with HDI Features

- Blind & Buried Vias

- Flex & Rigid-Flex boards