Tools for Designers:

BOM Checker

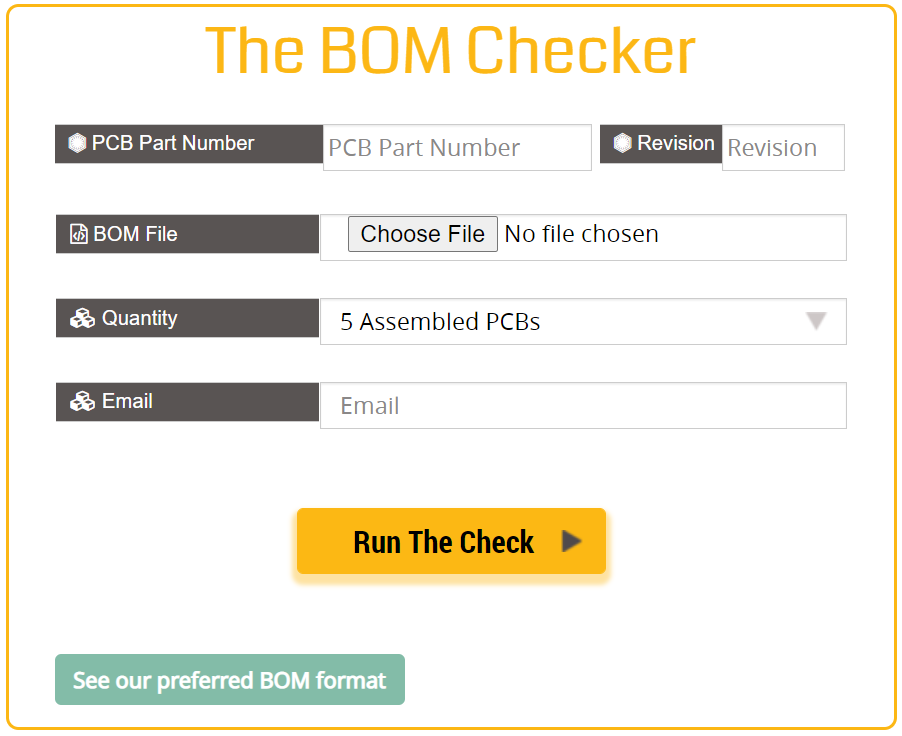

Upload Your BOMDownload our preferred BOM format

The BOM Checker tool helps get all the required assessments of a BOM for assembly. There is no need to check various software and websites to get hold of the required information. This tool points out all the errors associated with the uploaded BOM and helps get a cost estimate for the required number of PCBs. It also gives the user an idea about the availability of the parts and their life cycles from a set of vendors.

What is a bill of materials and how do you manage it?

A bill of materials (BOM) in PCB design is a list consisting of all the components to be assembled on a circuit board. This list will include the parts, their quantity, and other important details. Sorting out the required components for a given number of boards becomes an easy task when a proper BOM is present.

Creating and managing a bill of materials file can be done using BOM tools and ECAD tools.

Manufacturers always depend on the BOM files for assembly. All the information regarding the components required by the customer is conveyed through this file. The customer can also estimate the cost for the required number of boards.

How to build a BOM for PCB assembly

When it comes to PCB assembly, the manufacturer must have a clear idea about the components that are to be mounted. Hence, the BOM serves as a reference document. The part information required in a bill of materials includes quantity, reference designators, manufacturer part numbers (MPN)/vendor part numbers (VPN), footprints, etc.

How to create the best BOM for your PCB

Most companies accept BOM in Excel format. To create the best format for your PCB assembly, you have two options. One is manually creating a spreadsheet in the same template as required by your assembly vendor. This is a tedious task as it requires you to check for the stock status, pricing, and life cycle of each part in various component vendor websites. The second option is to use PCB design tools like Altium Designer, Allegro PCB Editor, KiCad, etc. They offer a bill of materials generation option to generate a BOM file as per requirement.

The advantages of the BOM Checker tool

The BOM Checker tool helps designers check for mistakes in their bill of materials before sending it for a quote. It also helps purchase the parts from a particular list of vendors in the market and resolve all other BOM issues.

Our BOM template can be downloaded from our tool using the option “See our preferred BOM format”.

The fields that are required in the bill of materials are:

- Quantity per board

- Manufacturer part number (MPN)

- Do not install (DNI)

- Reference designators assigned to each part

- Vendor name (optional)

- Vendor part number (optional)

- Value (optional)

- Size/footprint (optional)

- Part description/specs (recommended)

- Manufacturer name (optional)

Our tool checks for the following errors:

- Duplication of reference designators

- Compares reference designators with their quantity mentioned

- Duplication of manufacturer part numbers

- Incorrectly specified range of reference designators

Once the above errors are rectified, the tool helps you resolve component issues like long lead times, lifecycle issues, and so on. How the tool assists in resolving these issues can be found in stage 3: the pricing and availability section.

How to run the BOM Checker tool

First, you can download Sierra Circuits’ preferred BOM format. After downloading and referring to the template, generate your own bill of materials and upload it. Keep the details such as the PCB part number, revision status, and total quantity required ready before hitting “Run The Check”.

Stage 1: Verification for part number duplication

Here, the BOM Checker will show the issues regarding the duplication of part numbers, if any.

Duplicated part numbers will be pointed out by the tool. You can rectify the errors and re-upload the BOM file using the “Upload New BOM” option.

Stage 2: Verification of reference designators

Once the new BOM with no duplicate part numbers is uploaded, the tool checks it again for errors regarding reference designators.

It now ensures that the same reference designators have not been assigned to different part numbers. It also finds mismatches between the quantity and reference designators given.

In this step, you have the option to make the changes in the same window and it will be automatically applied to the BOM file. Or you have the option to upload a new rectified BOM.

Once these errors are cleared, the option saying “BOM is Clean-Check Availability” will appear. It allows you to explore the availability of the parts.

Stage 3: Pricing and availability

Since all the errors related to part numbers and reference designators have been corrected, the BOM Checker now assists in getting a quote.

The tool checks with the list of vendors for the quantities of the parts required and shows the results for the best option available. The list of vendors with which our tool checks for part availability are Digi-Key Electronics, Mouser Electronics, Coilcraft, Newark Electronics, Arrow Electronics, TTI Inc., and Future Electronics.

Our BOM tool also checks for issues like long lead time, obsolete life cycle, etc. and gives three options for the parts which have any of these issues:

- DNI: It stands for do not install. By clicking on this option, the designer is choosing not to install the particular part. Please note that this does not delete that part from the BOM, it just excludes this part while pricing and quoting.

- Resolve: Upon choosing Resolve, another page shows up with alternate part numbers that can replace the existing part.

- Get assistance: If there are no substitute parts found for a particular part, or if more information regarding replacement is needed, the “Get Assistance” option can be used. This connects directly to Sierra Circuits’ component engineering assistance chat window. Also, you can drop a message/inquiry which will be taken care of by the component engineering assistance services team as soon as possible.

Stage 4: Final cost and quote

After the issues regarding the parts are resolved, the final pricing page appears. This page shows the price of each and every part. You can either choose to go forward or select any of the two options given: “I will provide” or “DNI”.

If the “I will provide” option is chosen, the part will not be priced and you have to provide that particular part. “DNI” will put the part in the “do not install” list and will not be priced or installed.

After choosing these options as per requirement, the final price for all the parts given in the BOM will show up. From there, you can directly request a quote for assembling a PCB with the same BOM.

Sierra Circuits’ BOM Checker is a unique and easy-to-use tool that cleans a bill of materials from all possible errors and helps place a hassle-free quote.

Sierra Circuits has developed easy-to-use tools for PCB Designers and Electrical Engineers at every stage of circuit board development.

Fabrication, Procurement, & Assembly. PCBs fully assembled in as fast as 5 days.

- Bundled together in an entirely-online process

- Reviewed and tested by Engineers

- DFA & DFM Checks on every order

- Shipped from Silicon Valley in as fast as 5 days

Fabrication. Procurement & Assembly optional. Flexible and transparent for advanced creators.

- Rigid PCBs, built to IPC-6012 Class 2 Specs

- 2 mil (0.002″) trace / space

- DFM Checks on every order

- 24-hour turn-times available

Complex technology, with a dedicated CAM Engineer. Stack-up assistance included.

- Complex PCB requirements

- Mil-Spec & Class 3 with HDI Features

- Blind & Buried Vias

- Flex & Rigid-Flex boards