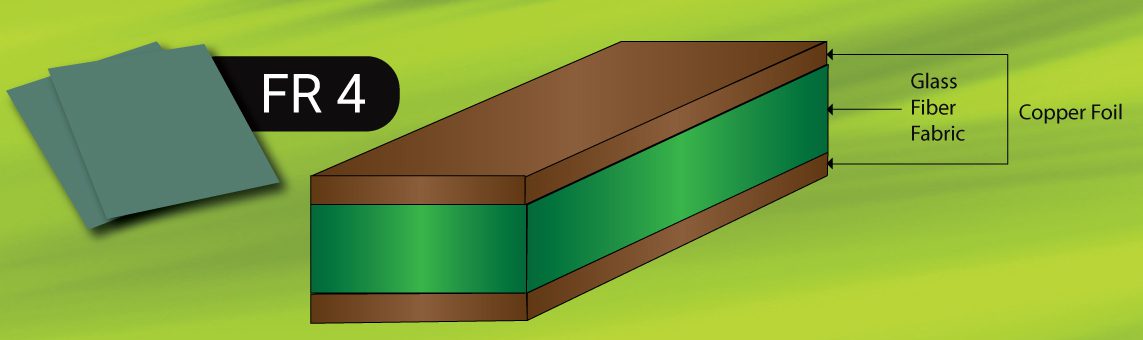

PCBs are made of non-conductive laminates (dielectric material) and conductive metal films. Laminates are obtained from substrate materials like FR-4, ceramic, and composite epoxy materials (CEM).

What is a PCB substrate?

A board substrate (core) is a dielectric material most commonly composed of epoxy resin and glass fiber weave (sometimes unwoven). These materials may be supplemented by ceramics to increase the dielectric constant. The substrate material chosen will determine the mechanical, thermal, and chemical properties of a circuit board. If the design requires better thermal performance, then go for a ceramic-based substrate.

Properties of board substrates

Dielectric materials provide electrical insulation between conducting layers. The properties of these dielectric materials dictate the performance of a PCB under different operating conditions, such as high-frequency and high-temperature.

Properties of PCB substrates can be broadly classified into:

- Electrical properties

- Thermal properties

- Chemical properties

- Mechanical properties

Electrical properties

Dielectric constant or relative permittivity (Er or Dk)

Considering the dielectric constant of a material is important for signal integrity and impedance considerations, which are critical factors for high-frequency electrical performance. The Er for most circuit board materials is in the range of 2.5 to 4.5. For higher frequency boards, lower Er values (3.2 to 3.6) are preferred.

Dielectric loss tangent or dissipation factor (Tan δ or Df)

A material’s loss tangent gives a measure of the power lost due to the material. The lower a material’s loss tangent, the lesser will be the power lost. The Tan δ of materials ranges from 0.02 for commonly used materials to 0.001 for very low-loss high-end materials. It also varies with frequency – increases as frequency increases.

Thermal properties

The thermal properties of a PCB substrate plays an important role in the assembly stage. These thermal properties include:

Glass transition temperature (Tg): It is the temperature range in which a substrate transitions from a glassy, rigid state to a softened, deformed state as polymer chains become more mobile.

Decomposition temperature (Td): It is the temperature at which a material chemically decomposes (the material loses at least 5% of mass).

- A material’s Td is an important factor when assembling PCBs because when a material reaches or surpasses its Td, changes to its properties are not reversible. This is in contrast to Tg, where properties will return to their original states once the material cools below the Tg range.

- Choose a material where you can work in a temperature range that’s higher than Tg but well below Td. Most solder temperatures during board assembly are in the 200ºC to 260ºC range, so make sure Td is higher than this.

Coefficient of thermal expansion (CTE): The coefficient of thermal expansion, is the rate of expansion of a circuit board material when it heats up. CTE is measured in three dimensions (X, Y, and Z).

Thermal conductivity (k): Thermal conductivity is the property of a material to conduct heat; low thermal conductivity means low heat transfer while high conductivity means high heat transfer.

Chemical properties

The chemical properties of the dielectric material impact the thermal and electrical properties of a board. It also affects the ability of the board to resist conductive anode filament (CAF) formation. Some of the chemical properties are discussed below:

- Moisture absorption: Moisture absorption is the ability of a substrate to resist water absorption when immersed in water. It is given by the percentage increase in the weight of a PCB material due to water absorption under controlled conditions as per standard test methods. Most of the materials have moisture absorption values in the range of 0.01% to 0.20%.

- Methylene chloride resistance: It is the ability of a material to resist methylene chloride absorption. It is expressed by the percentage increase in the weight of a circuit board material due to exposure to or soaking in methylene chloride under controlled conditions. Most of the materials have methylene chloride resistance values in the range of 0.01% to 0.20%.

Mechanical properties

The mechanical properties of a material determine its ability to withstand external loads without losing its characteristics. Few of the mechanical properties are listed here:

- Peel strength: Peel strength is a measure of the bond strength between the copper conductor and the dielectric material. It is expressed in pounds of force per linear inch. (PLI)

- Tensile (Young’s) modulus or elastic modulus: It is a measure of the stiffness of a solid material or the amount of force required to deform a material. It is defined as the ratio of the stress (force per unit area) along an axis to the strain (ratio of deformation over initial length) along that axis in the range of stress in which Hooke’s law holds good i.e., the stress-strain curve is linear. It is expressed as Pascals or pounds (force) per square-inch (psi).

- Flexural strength or bend strength: It is a measure of a material’s capability to withstand mechanical stress without fracturing when a PCB is supported at the ends and is loaded in the center.

- Tensile strength: It is a measure of a material’s maximum stress it can take before breaking, while being pulled from both sides. It is expressed as Pascals or pounds/square-inch (psi).

You can find more details about these in PCB Substrates: Knowing Your Dielectric Material’s Properties.

PCB Material Design Guide

9 Chapters - 30 Pages - 40 Minute ReadWhat's Inside:

- Basic properties of the dielectric material to be considered

- Signal loss in PCB substrates

- Copper foil selection

- Key considerations for choosing PCB materials

Download Now

What are the different types of PCB materials?

Board laminates are of different types. They include FR1 through FR6, CEM-1 through CEM5, G-10 and G-11 materials. FR-4 material is commonly employed as a substrate material for rigid circuit board fabrication.

Why FR-4?

FR-4 is a variant of fire retardant material that is used in boar fabrication. Today, FR-4 substrates are widely used across the industry. These materials are used to manufacture single-sided, double-sided, and multi-layered boards. Below are a few qualities of FR-4 materials that made them popular:

- Wide range of operating temperatures (50°C to 115°C)

- Higher Tg value (about 180°C)

- Offer decent mechanical properties to maintain board structure integrity

What substrates are used in flex PCBs?

Flexible boards require a substrate material that can be bent and twisted without breaking. Polyimide material is a commonly used substrate in flex circuits. The thickness of these materials does not exceed 120 µm.

Material selection plays an important role in board design. The temperature and mechanical requirements should always be considered while selecting a substrate material.