Kitting in PCB assembly is driven by growing customization and usage of component variants essential for assembly. Following the specific Sierra Circuits kitting guidelines is crucial to obtaining high-quality products at competitive pricing.

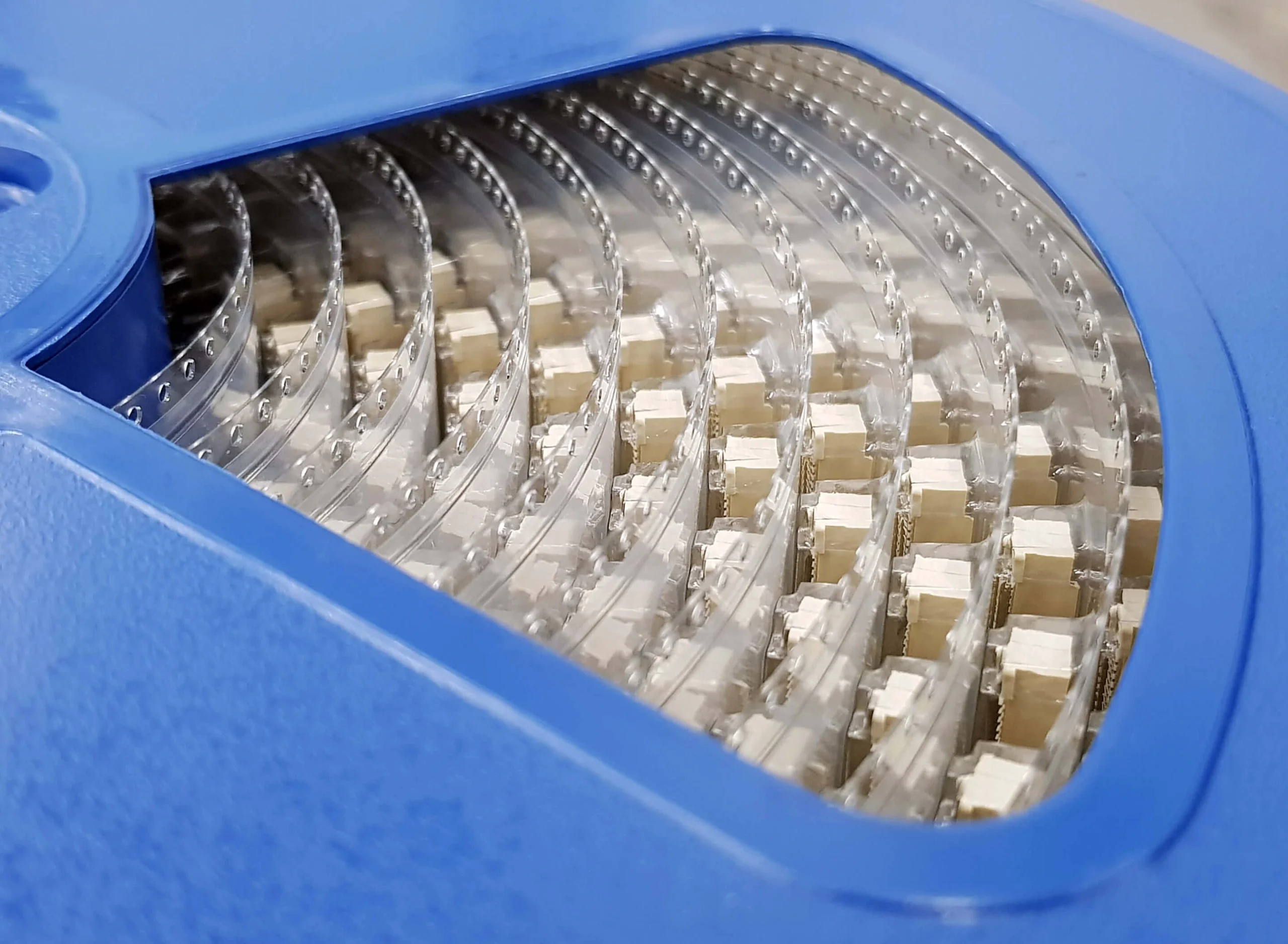

Please, note: Parts to be provided in tape. If parts are not available in tape, then tube/tray is acceptable. There may be an extra charge for tube/tray.

What is kitting in PCB assembly?

Kitting is the process of putting together a set of components as a kit required to assemble circuit boards. Here, the customer provides all the components that go on the board. Kitting brings all the materials/parts into one single package. It is extremely beneficial for the commencement of assembly since all the required components are available, verified, and placed in appropriate packaging.

Every board design and quantity requirements vary according to the customer. Hence, the kit criteria for each assembly project are different. In spite of these, there are particular rules to consider and standards to follow. The analogy could be that of cooking a recipe when all the ingredients are collected either from the market or from the kitchen and pantry. All these ingredients are brought together on the kitchen table and then cooked.

Design for Assembly Handbook

6 Chapters - 50 Pages - 70 Minute ReadWhat's Inside:

- Recommended layout for components

- Common PCB assembly defects

- Factors that impact the cost of the PCB assembly, including:

- Component packages

- Board assembly volumes

Download Now

Kit criteria for components

Below is the list of approximated kit guidelines for each component.

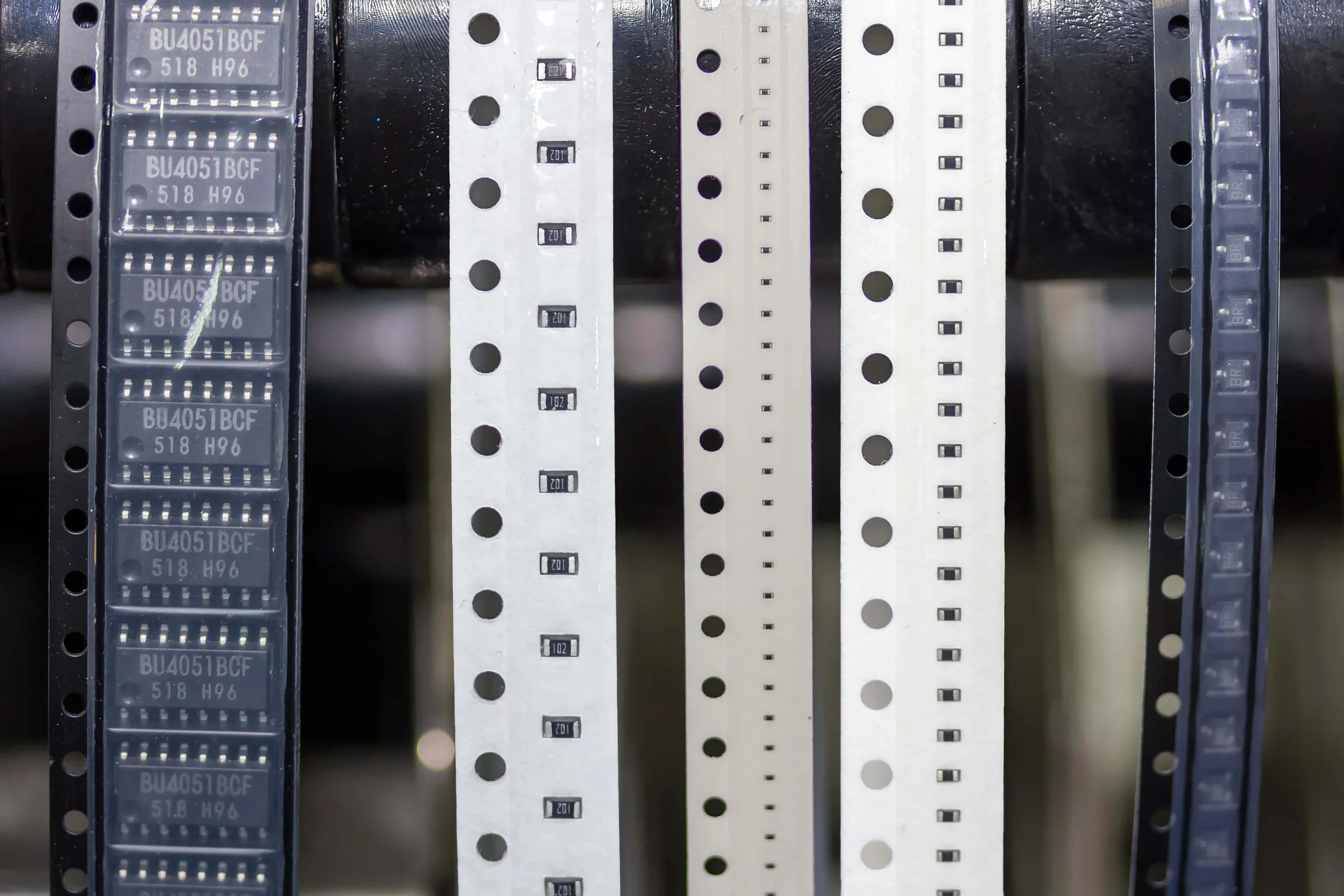

SMDs

Leaded components or ICs

- These parts should be sent in properly packaged containers (tubes, trays, or taps). Parts should be loaded in such a way that Pin1 should remain consistently in the same direction. Otherwise, it will cause directional placement issues, resulting in compromised quality.

- If the parts are handled manually, it can lead to coplanarity problems.

Digital signal processing chips (DSPs) and other ICs

- Usually, these components require special handling. For example, moisture-sensitive components need baking. These should be sealed. If opened, they must be resealed according to specific techniques. In most cases, waffle trays are used for handling such parts.

Passive parts

- Passive components like capacitors and resistors should be in proper pick and place format.

- Include a few parts for attrition.

Connectors

- For these parts, the original waffle packaging should be utilized to prevent damage to the leads.

Stencils

- Engineers will review the stencil supplied by the customer to ensure production and machine compatibility.

Through-hole components

Sockets

- These sockets should be delivered in their original packaging to avoid damaged or bent leads. These parts will create several manufacturing and quality flaws if sent otherwise.

DIP packages

- These components can be supplied in tubes or in loose form.

Leaded parts

- Typically, these components should be packed on reels to maintain their quality. Loose parts are also acceptable if they are properly packed and not oxidized in any way.

Important Sierra Circuits kitting guidelines

If you are asking for a consigned assembly (partial turnkey) quote, make sure to send all the required components for assembly while placing an order. Here are some critical Sierra Circuits kitting guidelines:

1. Each SMD line item should be on a single continuous tape (Please, follow minimum reel length requirements as per kitting/attrition guidelines. Must be continuous tape; no splicing allowed). If not placed on a tape or reel, they must be on trays or tubes.

2. When shipping multiple work orders in one box, each work order must be individually packaged with its own set of components.

3. When you place an order and intend to consign components, Sierra Circuits will send you a Customer Consigned Inventory (CCI) form. The attrition quantity guidelines will be on the form. Please follow those guidelines. Lack of proper attrition quantity will be treated as parts shortage.

4. USE OUR CUSTOMER CONSIGNED INVENTORY Form (CCI form)

- When you send us consigned items, the package must be accompanied by our CCI form. You will receive a CCI form by email shortly after you place an order that has consigned items. The CCI form is pre-filled with all the expected consigned components and the required quantities including attrition. You will also have guidelines at the bottom of the CCI form regarding our attrition policies. If you do not receive a CCI form, please ask your salesperson for it, or you can find it on the customer portal.

- If you are consigning parts for multiple work orders, please send us separate boxes with individual work orders. Do not mix parts from different work orders in the same box.

- Please, follow the CCI form for guidance on how much attrition quantity to provide.

- Restrictions on consigned components: Sierra Circuits prefers to buy the components for assembly from our approved vendors for better efficiency and counterfeit prevention. If customers do have to consign components, we expect them to consign us only hard-to-find parts or their custom parts. Specifically, we do not allow consigning of SMD resistors and capacitors unless these passives are not available in the open market.

- Handling charges for consigned components: Every consigned line item will incur a $7 handling fee, generally added to our assembly labor quote. For example, if you have 3 different line items being consigned (i.e., 3 different MPNs, whatever the quantity), we will add a $21 charge for handling these consigned items.

- The CCI form quantity is shortage plus attrition, so the customer should not be expecting parts back. PLEASE DO NOT send more than requested quantity on CCI form, unused attrition will be scrapped. If a customer requests to return unused attrition, there will be a charge of $300.

If you are asking for full turnkey assembly, we will take care of all kitting requirements so you don’t have to.

Ship any consigned material to:

Attn: Consigned Material Receiving ( )

Sierra Assembly

1980 Lundy Avenue

San Jose, CA 95131

USA

You MUST mention either quote number, order number, or Inventory number in the ( ) on Attn: line.

If consigned items are being sent to Sierra Circuits from outside USA, please note the following:

- The customer/shipper is responsible for all customs & duties and must claim this when they fill out the freight waybill. When filling out the waybill, there is an option to check the shipper as being responsible for customs/duty. Please ensure that this is checked so that the shipper is responsible, not Sierra Circuits.

- If, for any reason, Sierra Circuits does end up receiving a bill for customs and duty, Sierra will add these charges to the customer invoice and add a minimum $150 administrative/handling fee on top.

- Parts to be provided in tape. If parts are not available in tape, then tube/tray is acceptable. There may be an extra charge for tube/tray.

See our FAQs on customer consigned inventory for guidance on a successful consignment.