The IPC-1601 A standard outlines the best practices for printed board packaging and shipment.

At Sierra Circuits, we follow these guidelines to ensure board reliability. These standards are equally valuable for electronic device manufacturers, who store and manage circuit boards throughout their operations.

As a PCB designer, it is important to understand how your fab house handles and stores your boards. Any missteps during this stage, such as improper packaging or storage conditions, can negatively impact the quality and reliability of the final product.

Here, you’ll learn how we tackle moisture-related issues at our fab house and the best circuit storage practices an electronic manufacturer should follow.

What is IPC-1601 A?

IPC-1601 A is the industry standard for the handling, packaging, and storing of printed circuit boards. It is developed to provide comprehensive guidelines for protecting bare boards and PCBAs from contamination, physical damage, and moisture absorption during storage and transportation.

Why is the IPC-1601 A standard important?

Circuit boards are susceptible to threats like electrostatic discharge (ESD) and physical damage. Here’s why you need to follow the standard when dealing with PCBs:

- Prevents contamination from dirt, dust, and other substances.

- Protects against physical damage such as scratches, cracks, and other physical defects caused by rough handling or inadequate packaging.

- Shields against electrostatic discharge (ESD) to safeguard sensitive components.

- Limits moisture absorption to minimize the risk of delamination and poor soldering.

IPC-1601 A recommendations for moisture management in PCBs

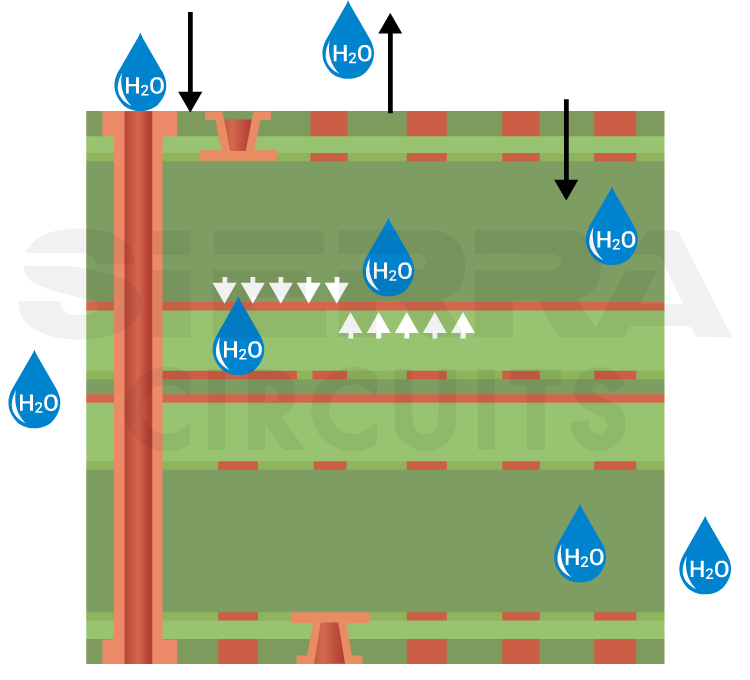

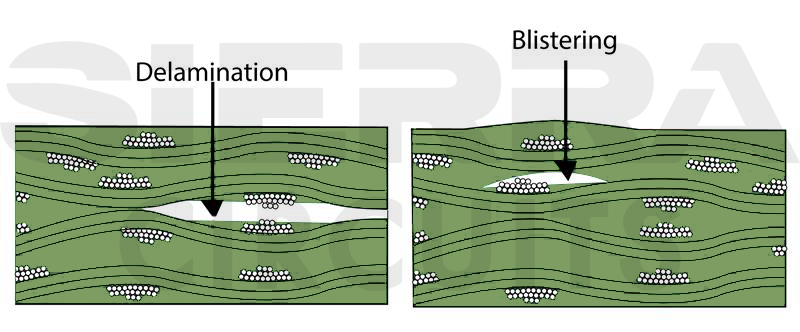

The moisture absorption rate of circuit board substrates increases when exposed to soldering temperatures. This can result in internal delamination, blistering, cracking, and damage in plated-through holes.

Additionally, the transition to lead-free soldering has brought about 30-40°C higher reflow and wave soldering temperatures. This leads to longer exposure times that may increase the risk of moisture-related failures.

Here are a few guidelines that we follow for effective moisture management:

- Ensure the MAMC (maximum moisture content) is between 0.1% to 0.5% of the total resin weight.

- Preheat the boards before assembly to eliminate absorbed moisture.

- Set the baking temperature in the range of 100- 125°C but below the glass transition temperature (Tg) of the board material.

- Incorporate a forced-air recirculating oven for even heat distribution.

- Do not overstack the boards inside the oven, as this can block airflow and create uneven heating. Limit stack height to 25.4mm for uniform heating.

- Maintain proper venting and ensure the oven is clean to prevent contamination during the baking process.

- Create customized baking profiles based on board complexity, thickness, and finish to ensure optimal moisture removal without damaging the board.

- After baking, cool the material quickly in a dry environment, as hot materials can quickly absorb moisture in humid conditions.

- Minimize the time between baking and lamination to reduce moisture absorption. Table 2.2.1 in IPC-1601 A shows typical recommendations for oven settings for different PCB surface finishes.

- For moisture-sensitive materials, adhere to MSL standards defined by IPC J-STD-033 or IPC J-STD-020, as shown in the table below. It specifies how long a board can be exposed to ambient conditions before it needs re-baking or dry packaging to eliminate absorbed moisture.

| MSL level | Floor life | Storage temperature/Humidity | Dry packing requirement |

|---|---|---|---|

| MSL 1 | Unlimited | ≤30°C/85% RH | No |

| MSL 2 | One year | ≤30°C/60% RH | Yes |

| MSL 2a | 4 weeks | ≤30°C/60% RH | Yes |

| MSL 3 | 168 hours | ≤30°C/60% RH | Yes |

| MSL 4 | 72 hours | ≤30°C/60% RH | Yes |

| MSL 5 | 48 hours | ≤30°C/60% RH | Yes |

| MSL 5a | 24 hours | ≤30°C/60% RH | Yes |

| MSL 6 | Mandatory bake before use | N/A | Yes |

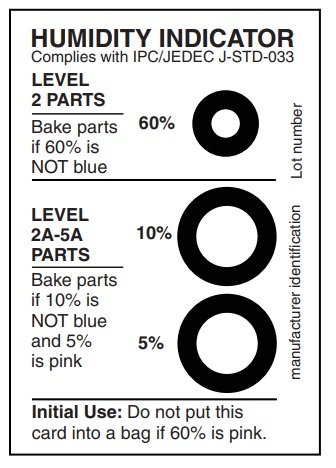

- Include a humidity indicator card (HIC) for moisture-sensitive components. They track internal humidity and signal high moisture levels.

IPC 1601 A humidity indicator card is placed in a moisture barrier bag. Image credit: IPC. - Store electronic components in a low-humidity environment (≤5% RH). If any components are not used, reseal them in the MBB.

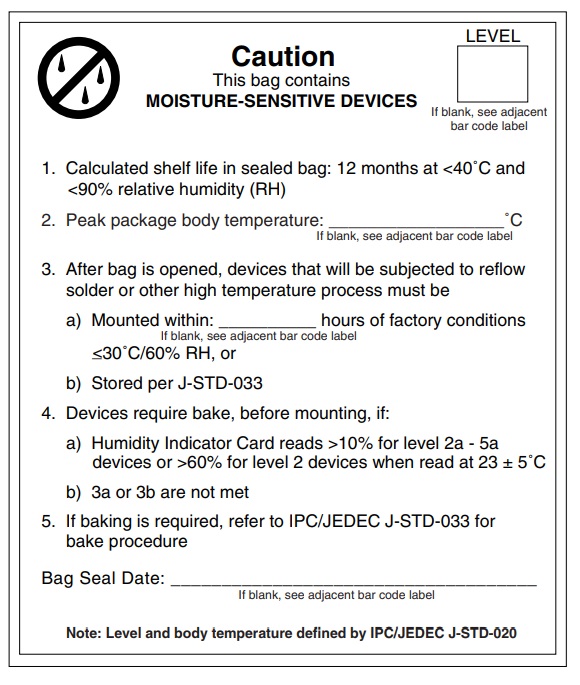

- If a board has moisture-sensitive components, pack it using a moisture barrier bag (MBB) with desiccant and a HIC.

Moisture-sensitive caution label. Image credit: IPC. - Do not bake the boards with OSP (organic solderability preservative) coatings. If baking is necessary, use the lowest possible temperature and dwell time.

For design for manufacturing guidelines, download our eBook.

Design for Manufacturing Handbook

10 Chapters - 40 Pages - 45 Minute ReadWhat's Inside:

- Annular rings: avoid drill breakouts

- Vias: optimize your design

- Trace width and space: follow the best practices

- Solder mask and silkscreen: get the must-knows

Download Now

12 guidelines for packing circuit boards

We follow these strict packaging rules defined by IPC-1601 A to ensure boards reach our customers in flawless condition:

- For temporary storage (within the production cycle) before shipping, use dry packs.

- When packaging immersion silver boards, use sulfur-free and pH-neutral packaging materials.

- For lead-free boards, use packaging material with a metallic inner layer to prevent moisture absorption.

- Remove any moisture before packaging the PCB assembly process.

- Include vacuum-sealed moisture barrier bags, humidity indicator cards, and desiccants.

- For flexible, odd-shaped, and thin (< 1.40 mm thickness) boards, include rigid protective backing to prevent mechanical impact.

- Use ESD-compliant materials to avoid damage due to electrostatic discharge.

- Comply with ANSI standards when labeling ESD-sensitive circuit boards.

- Incorporate appropriate warnings or symbols for printed boards with moisture-sensitive components.

Moisture-sensitive identification label. - Determine the number of boards per package based on area, thickness, and circuit complexity.

- For boards measuring ≤ 144 inches² (0.09 m²), limit packaging to 25 units per delivery unit.

- For boards measuring > 144 inches² (0.09 m²), limit packaging to 10 units per delivery unit.

- Use sulfur and chloride-free release paper to prevent contamination and ensure easy removal of the PCBs from the packaging.

- Avoid completely removing air during vacuum sealing to maintain the effectiveness of the desiccant.

Sierra Circuits fabricates high-quality circuit boards right here in the United States. To learn more, visit PCB manufacturing capabilities.

8 PCB storage guidelines for electronic device manufacturers

As an electronic device manufacturer, you may need to store PCBs from your fab house at your facility before deploying them into the final product. It is crucial to follow IPC 1601 A storage guidelines to increase the shelf life of your boards:

- Store your boards in a stable and dry environment with controlled temperature (range 15°C to 30°C) and with relative humidity levels of 40% to 65% to prevent damage from fluctuations.

- Avoid storing in damp areas as they are sensitive to humidity. Utilize desiccants or humidity control devices to maintain optimal moisture levels.

- Use covers or packaging to prevent dust accumulation and ensure a clean storage environment.

- Protect from extended exposure to direct sunlight, as this can lead to material aging and degradation.

- Stock unused boards in anti-static bags, foam sheets, or similar materials to safeguard them from mechanical and environmental damage.

- Store PCBs in ESD-free racks to shield against electrostatic discharge.

- Label each unit with details such as model, batch number, and storage date for easier tracking and management.

- Conduct regular inspections of stored boards to ensure their packaging remains intact.

6 best circuit board handling practices for IPC-1601 A compliance

- Limit direct contact with PCBs whenever possible.

- Use racks, tray carts, and protective bags for transportation within the facility.

- If handling is necessary, hold the boards by their edges and wear clean gloves (preferably ESD gloves and changing them frequently).

- Maintain cleanliness at all workstations, as this significantly lowers the chances of foreign object debris (FOD) contamination.

- Avoid using hand lotions or products that could compromise board quality.

- Ensure handling areas are free from items that can generate static electricity (e.g., carpets, rugs).

IPC-1601 A provides comprehensive guidelines to ensure the effective handling, storage, and management of PCBs throughout their lifecycle. By adopting these practices, organizations can enhance product quality, extend shelf life, and ensure the dependability of electronic devices.