What are countersink and counterbore holes in PCBs?

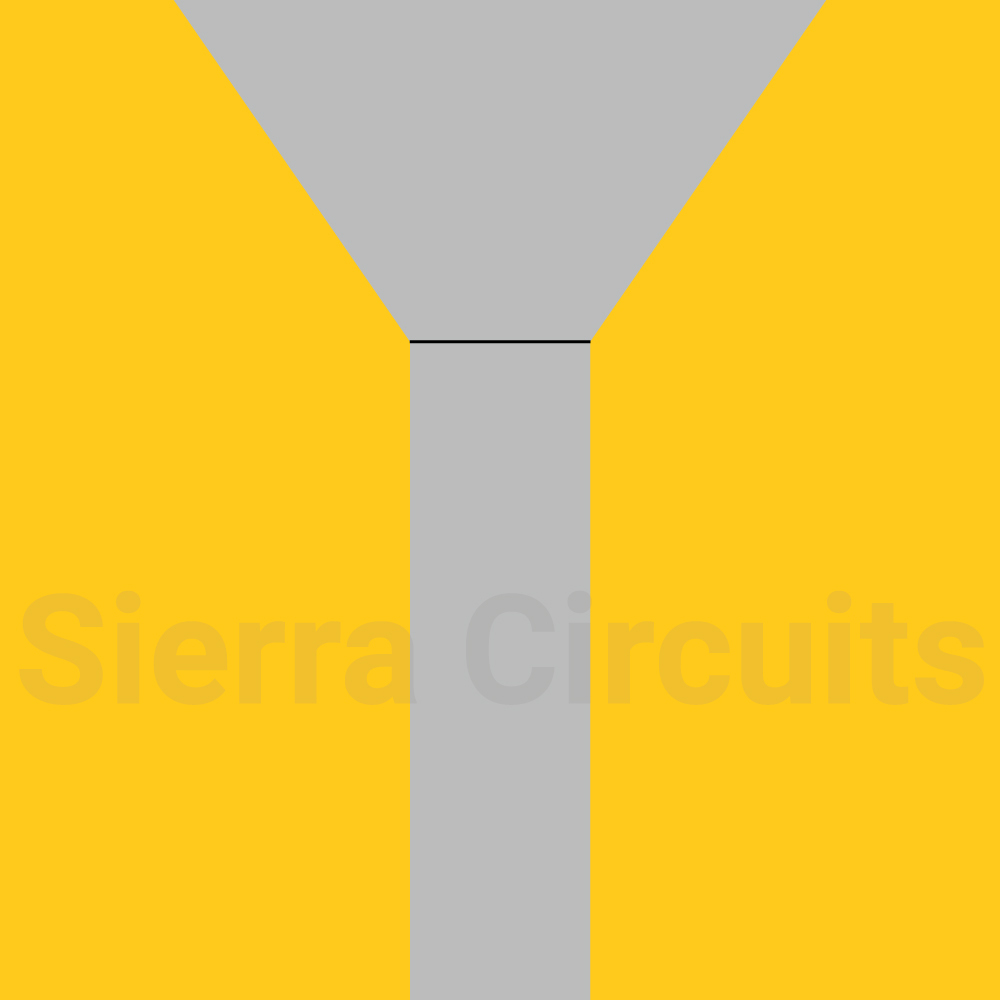

A countersink hole is a cone-shaped hole that is notched or drilled into a PCB laminate. This tapered hole allows a flat-head socket screw head to be inserted in the drilled hole. Countersinks are designed to allow the bolt or screw to stay tucked inside with a planarized board surface.

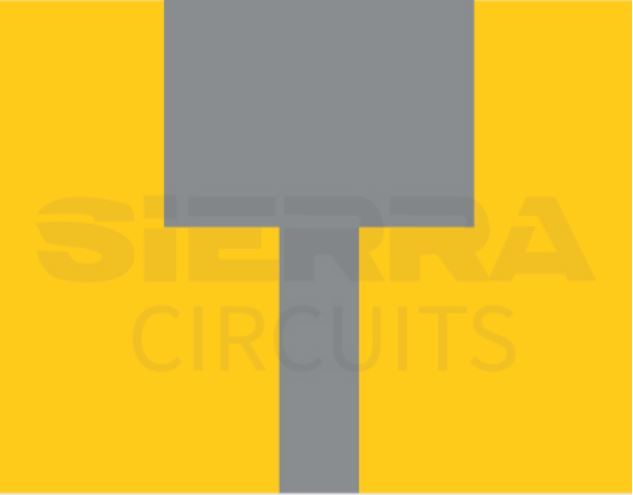

Counterbore drilling involves creating a flat-bottomed hole. The sides of these holes are parallel and vertically straight. Cylindrical-shaped counterbore allows a hex-headed screw to fit under the drilled hole. This hole is the bigger version of a coaxial hole.

PCB Material Design Guide

9 Chapters - 30 Pages - 40 Minute ReadWhat's Inside:

- Basic properties of the dielectric material to be considered

- Signal loss in PCB substrates

- Copper foil selection

- Key considerations for choosing PCB materials

Download Now

When to use countersink and counterbore holes

Countersink holes are implemented in compact designs where space is a critical constraint. The planarized surface makes room for more surface area. These are largely used in tight-fitting, compact applications to enhance flexibility and provide space for installation. For example, they are incorporated in smartphones and smartwatches.

Counterbore holes provide enough room to fix the sockets. They are the appropriate choice when your design requires strong attachment rather than space-saving and even surface finishes. These holes can be used in washers and other electronic devices where secured fitting is the primary concern.

Drilling requirements for countersink and counterbore

Countersink

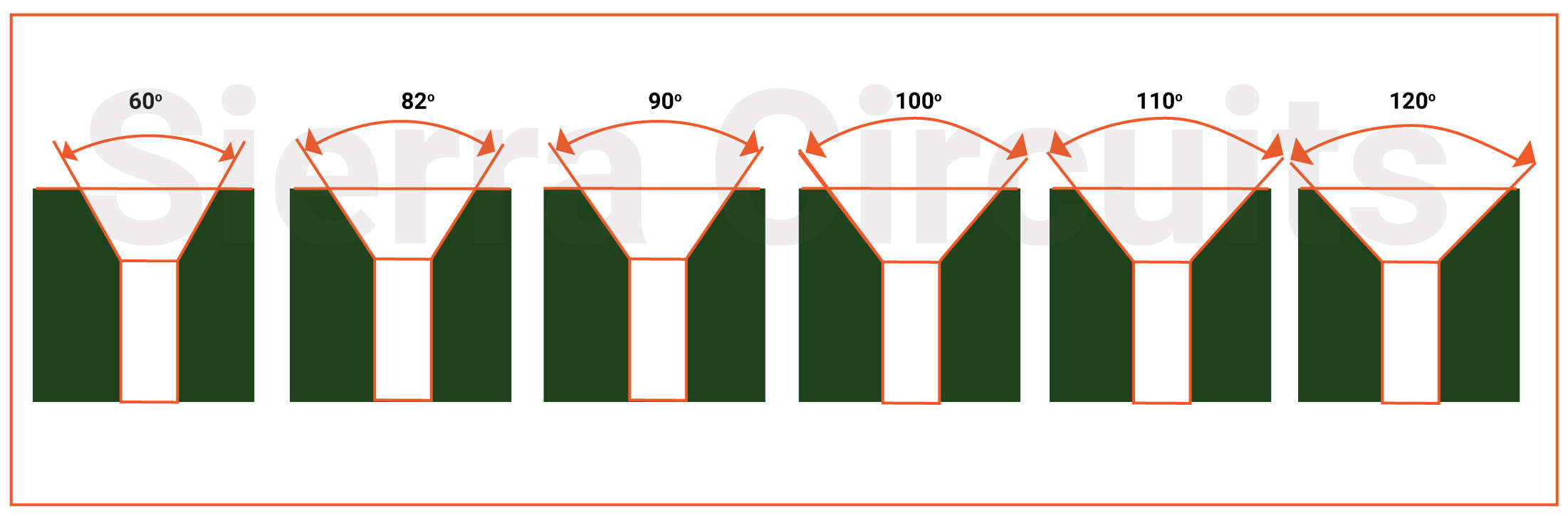

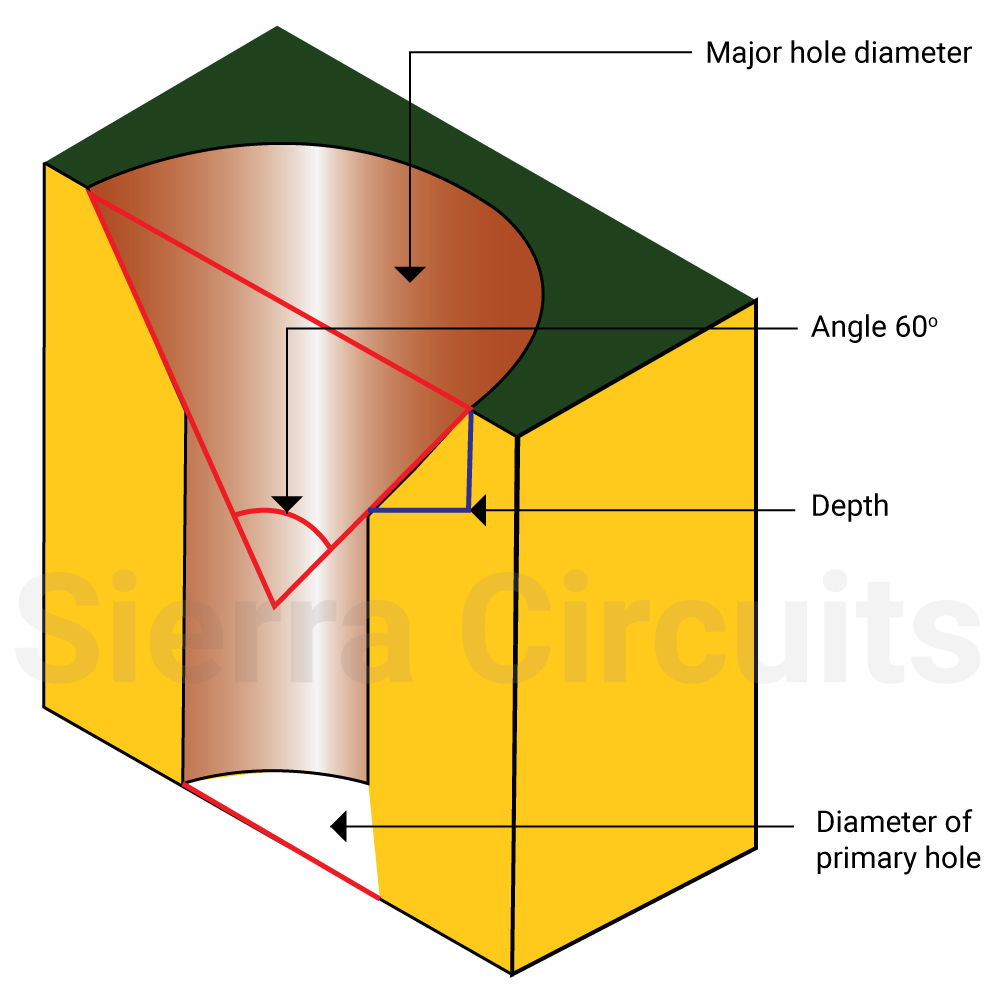

Conical countersink holes require great precision to accommodate screws with a flat head. These types of holes are bored into a PCB hence, determining the correct angle is vital. A wide range of drill bits with different angles is available for creating countersinks. Generally, the most commonly applied angles are 82°and 90°. Although, other angles like 60°, 100°, 110°, and 120° can also be included according to the design requirements. It is essential to match the angle of the larger hole with the tapered angle of the fastener.

The depth of the sink depends on the major hole diameter and the angle of the sink. If the major diameter remains unchanged, the depth varies inversely with the sinking angle.

To build a perfect countersink hole, the following information is needed:

- The angle of the drill bit.

- The countersink hole or major hole diameter and the standard through-hole or primary hole diameter.

- The side that needs a countersink hole.

- The depth of the drill hole.

- Whether the holes should be plated or non-plated.

Counterbore

The sides of the counterbore hole are parallel to each other and do not require any tapering. Hence, designers need not mention an angle to manufacture this.

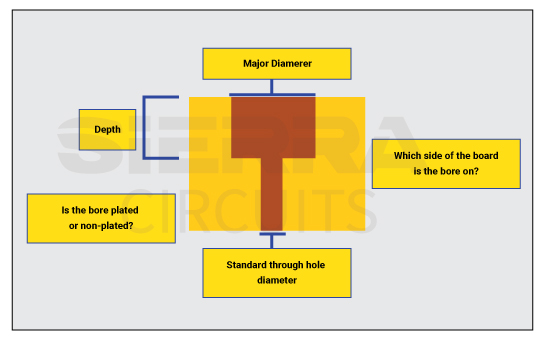

The details required to fabricate the counterbore are:

- Major diameter or finished diameter of the hole at the surface.

- Drilling depth of the counterbore hole.

- Where the bore needs to be drilled, top or bottom.

- The finished diameter of the shaft.

- Whether the bore and shaft are to be plated or non-plated.

Symbolic representation

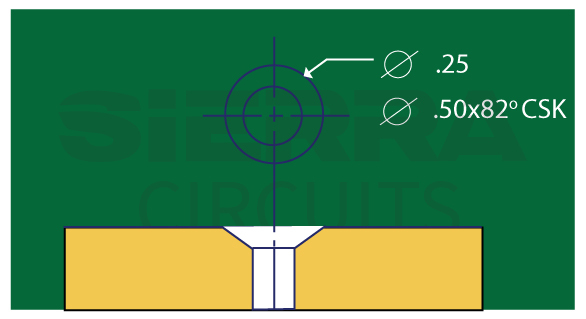

The countersink hole is represented by the letter ‘V’ with the numerical value of the diameter beside that. This symbol is picked up because the side view of the hole resembles the letter ‘V’. You can see the example below of a countersink symbol, where through hole diameter is mentioned as 0.25 mils, and countersink diameter and angle are 0.50 mils and 82°, respectively.

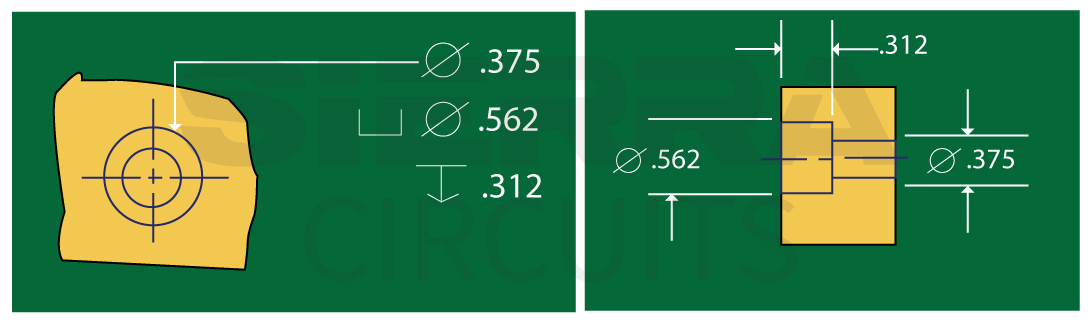

The counterbore resembles a square, opened from the top. These are specified with the drilling diameter, depth, and diameter of the counterbore. If the thickness of the material below the counterbore is significant, it is crucial to mention the material thickness rather than the hole depth.

Here, two kinds of counterbore symbols are shown. In both the images, you can see the major diameter is 0.375 mils, counterbore diameter is 0.562, and drill depth is 0.312 mils.

Countersink Vs. counterbore

| Characteristics | Countersink | Counterbore |

|---|---|---|

| Shape | Conical hole | Cylindrical, flat-bottomed hole |

| Angle | 82°, 90°, 60°, 100°, 110°, and 120° | No angle required |