Webinar: Improving PCB Performance with Embedded Resistors and Capacitors

REGISTER NOW

January 15th, 2025 at 10:00 am PT

COST: FREE

-

10

Days

-

11

Hours

-

50

Minutes

-

17

Seconds

John Andresakis

Director of Business Development at Quantic Ohmega-Ticer

Amit Bahl

CRO at Sierra Circuits

Online via Zoom

Following this event, you will receive:

-

Recording

-

Slides

-

Up to 25% off PCB fab and assembly

-

PCB resources

Webinar abstract:

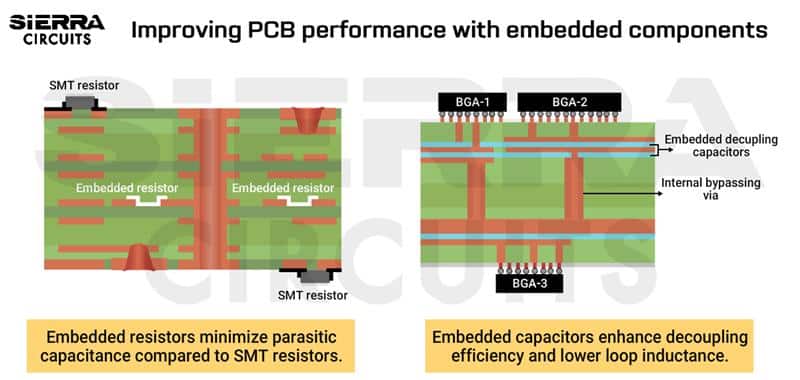

When designing RF or IoT circuit boards, incorporating embedded resistors and capacitors reduces parasitic effects and ensures reliable signal transmission. These passives save board real estate, enabling smaller form factors and higher component density. Furthermore, embedded passives enhance heat dissipation, reducing the risk of component overheating.

Register for this webinar to learn how to improve your PCB performance by implementing embedded components.

Designing reliable high-speed PCBs with embedded resistors and capacitors

Evaluate the resistance, including tolerances, when selecting embedded resistors. Incorrect resistance might cause mismatched impedance and signal reflection. Consider the maximum power the component must handle. Use resistors with a low TCR (below 100 ppm/°C) to minimize variations due to temperature fluctuations.

Embedded capacitors play a key role in reducing loop inductance. To achieve effective decoupling, place these capacitors as close as possible to the power pins of the ICs. Opt for capacitors with voltage ratings 2 to 3 times higher than the operational voltage to ensure reliability and prevent breakdown.

The choice of PCB laminates plays a critical role in embedded component designs. For high-frequency applications, select low-loss dielectric materials such as Rogers 4350B and Panasonic Megtron 6. Implement a symmetrical stack-up to ensure structural integrity. Additionally, use materials with consistent CTE to prevent delamination during manufacturing processes.

When routing, minimize the distance between embedded passives and active devices to reduce parasitics and noise. Route high-speed signals perpendicular to embedded resistors and capacitors to prevent coupling.

To maintain uniform impedance, keep trace widths and dielectric thicknesses consistent. Avoid abrupt changes in trace width, as these can lead to impedance discontinuities and signal reflections. Do not route long traces between signals and passive components. Incorporate solid ground planes and place them close to the signal layers to reduce loop inductance.

For effective heat dissipation, integrate thermal vias and copper pours. Consider external heat sinks for high-power designs.

Add XY coordinates and component specifications in your fab drawing for efficient prototype production.

In this webinar, our PCB experts will discuss the best practices for designing prototypes with embedded resistors and capacitors.

Register now!

Webinar agenda:

- Why embedded resistors and capacitors?

- Comparison between SMT and embedded components

- How embedded passives are fabricated

- 3 factors to consider when choosing embedded resistors

- Resistor types: printed, plated, thin-film, and thick-film

- Resistance and tolerance

- Power dissipation and current carrying capacity

- Selecting embedded capacitors: voltage rating and capacitance

- Design guidelines for PCBs with embedded passives

- Material selection and stack-up design tips

- How to ensure uniform impedance in your layout

- Decoupling strategies

- Best thermal management techniques for reliable designs

- Special instructions for your manufacturer

Director of Business Development, Quantic Ohmega-Ticer

John Andresakis has over 40 years of experience in the manufacturing of Printed Circuit Boards and related products. He joined Quantic Ohmega-Ticer in January 2023 and is now the Director of Business Development. He is working on expanding the market for the company’s novel thin film resistor technology. Before Quantic Ohmega, John was in Technical Marketing and Business Development for DuPont Interconnect Solutions Electronics group. He concentrated on identifying opportunities in the high-speed/high-frequency markets by working with major OEMs and helping shape the R&D team's efforts to develop new products. Before DuPont, he was the Director of Technical Marketing for Park Electrochemical (now AGC-Multi Materials), working on introducing and implementing new materials with Park’s OEM customers. Before Park, John was Vice President of Strategic Technology for Oak-Mitsui Technologies (a US subsidiary of Mitsui-Kinzoku of Japan). He developed the FaradFlex line of embedded capacitor materials and helped develop their low-profile copper offerings. In addition to Oak-Mitsui, John was in Technical Management at Hadco Corporation (now part of Sanmina Corporation), Park Electrochemical (Nelco), Digital Equipment, and IBM. He holds a Master’s degree in Chemical Engineering from the University of Connecticut and a Bachelor's in Chemical Engineering from The Cooper Union. He has received 10 US (and several foreign) patents related to PCB production and materials and is a member of several IPC committees that develop specifications for Embedded Passives, Printed Electronics, PCB Materials, and Test Methods.

CRO, Sierra Circuits

Amit Bahl, widely recognized as the PCB Guy, currently serves as the Chief Revenue Officer at Sierra Circuits. He earned his Bachelor of Science in Engineering from UCLA in 1997, launching his career in Silicon Valley's tech industry. In 2009, he assumed the role of Director of Sales and Marketing at Sierra Circuits, with a dedicated focus on democratizing design for manufacturing best practices and guidelines for PCB designers and engineers. Assuming the position of Chief Revenue Officer since 2022, Amit's mission persists: to simplify the PCB design journey for all stakeholders. His unwavering dedication continues to drive Sierra Circuits as a trusted resource for the PCB design community.