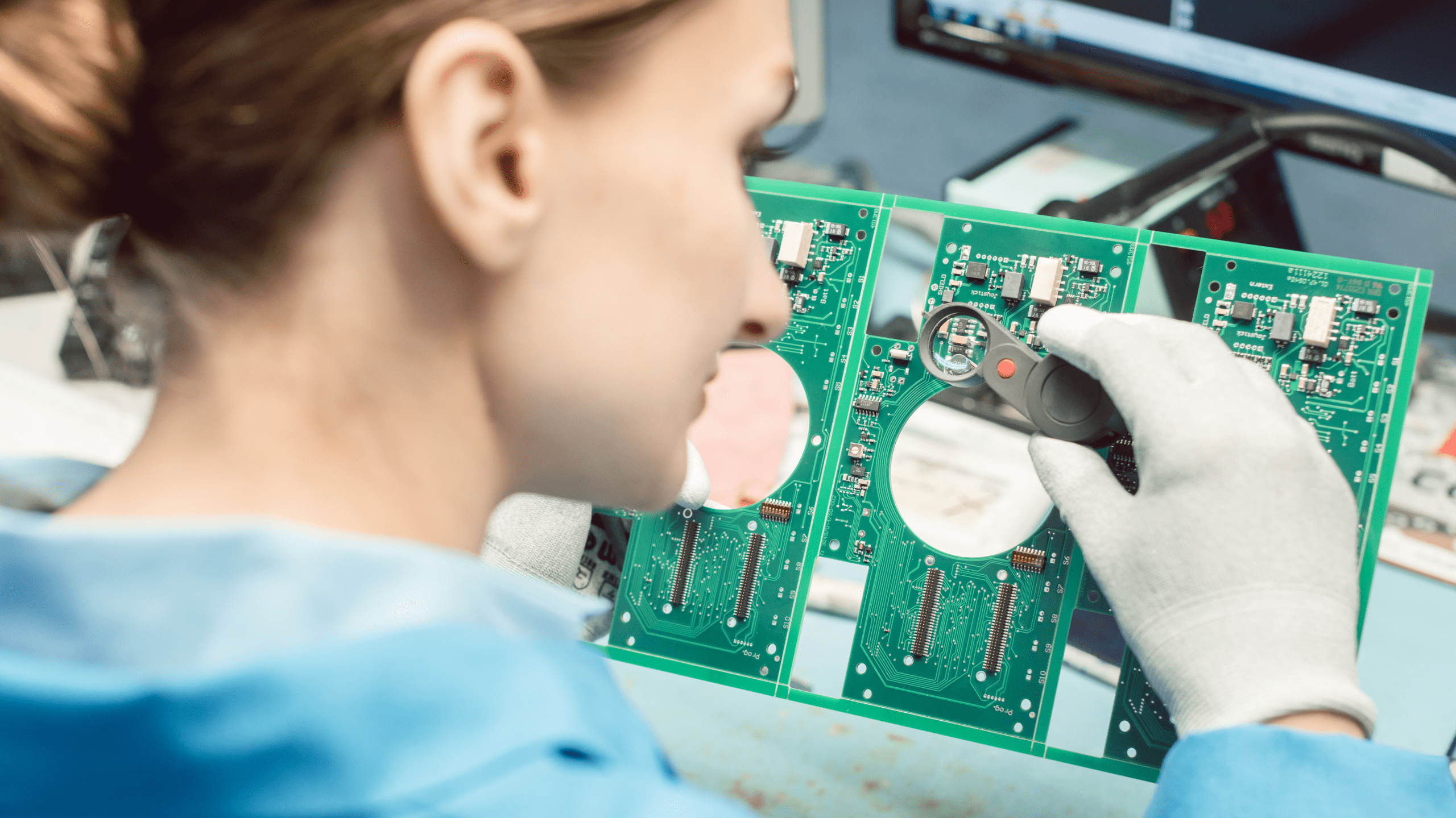

Introducing Design Modification Support:

Your Solution to Revamp Existing Designs

At Sierra Circuits, we understand that the journey from concept to prototype can be filled with challenges, especially when parts become unavailable or issues arise after prototyping. That's why we're excited to introduce our new service, design modification support, designed to address these specific needs and keep your project on track.

Post-prototype support

Issues after prototyping?

We’ve got you covered. Prototyping is a critical stage in design development. When issues surface post-prototyping, our team is here to assist. We provide expert guidance and modifications to refine your design, ensuring functionality, reliability, and manufacturability.

Parts unavailability

Parts not available?

No problem. In today’s dynamic market, component availability can be unpredictable. We step in to offer alternative solutions that keep your project on track without compromising on quality.

Schematic changes

Need to adjust your design?

We can help. When certain components become unavailable, it often necessitates changes in the schematic to accommodate different parts. Our team of experts will help you navigate these changes seamlessly, ensuring your design remains robust and functional. We analyze the impact of substituting components and make necessary adjustments to the schematic, so your design continues to meet its intended specifications and performance standards.

Layout changes

Our design modification support includes a variety of layout changes to enhance your design. But all of the below changes depend upon the complexity of the board, we will analyze it first and then update you about the scope of work, cost, and turn time.

Board size reduction

We can help reduce the size of your PCB to fit into smaller enclosures or meet space constraints, optimizing the board for better performance and cost efficiency.

Layer reduction

Simplifying your PCB by reducing the number of layers can lower manufacturing costs and improve signal integrity. Our experts offer support to rework your design to achieve the same functionality with fewer layers.

Component placement changes

Proper component placement is crucial for the performance and manufacturability of your PCB. We can adjust the placement of components to enhance thermal management, signal routing, and overall board layout.

Benefits of Design Modification

Reduced downtime

Get your project back on track quickly by avoiding delays caused by part shortages or design revisions.

Expert guidance

Leverage the expertise of our experienced engineers to identify the best solutions for your specific needs.

Cost-effective

Minimize the need for costly redesigns by adapting your existing layout.

Streamlined production

Ensure a smooth transition from prototype to full production with a design optimized for manufacturability.

Get Started Today:

Don't let parts availability or post-prototype issues delay your project. Contact us today to learn more about our design modification support and how we can help you overcome these challenges.

Book a meeting with an expert