Contents

On-demand webinar

How Good is My Shield? An Introduction to Transfer Impedance and Shielding Effectiveness

by Karen Burnham

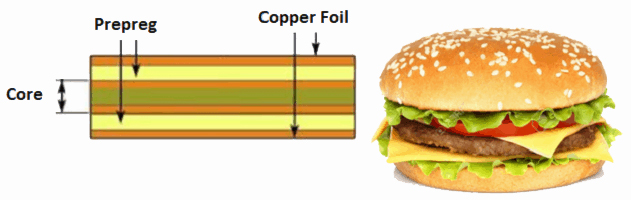

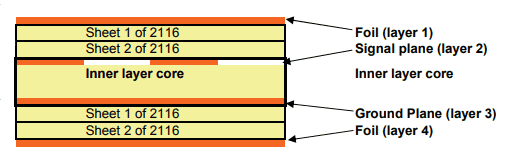

As simple as it is, a prepreg is nothing but an insulation layer. Prepreg is a dielectric material that is sandwiched between two cores or between a core and a copper foil in a PCB, to provide the required insulation. You can call it a binding material as well. It either binds two cores or a core and a copper foil. This plays a critical role in PCB design and manufacture.

If you can imagine a hamburger, prepreg is the slice of cheese placed between the bread and the ham. The bread and ham can either be a core or a copper foil. Now I am sure I got your attention.

I would like to tell you something interesting about prepregs. Prepregs are special dielectric materials that can be modified to our needs. By the combination of certain additives and catalysts, under a chemical process, a specific section of a prepreg can be transformed into a conductive region. This is called selective conductivity. This phenomenon finds its purpose while drilling holes into the prepregs for connecting the top and the bottom layers. However, the rest of the part of the prepreg remains to be an insulator and protects the circuit board from short circuit which is its basic functionality.

Years of immense research and development have been undertaken for the selection of the right prepreg material. Factors like thermal and mechanical compatibility of material must be considered to accommodate the PCB requirements.

How are prepregs made?

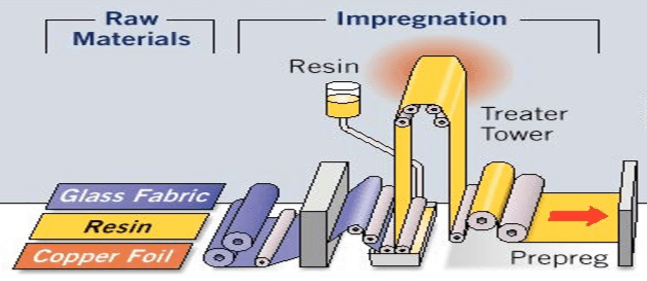

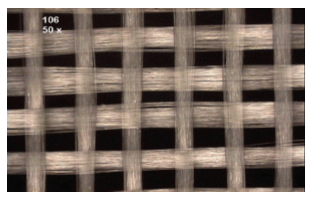

Prepreg, as the name suggests, is a glass fiber weave/cloth impregnated with a resin bonding agent. The glass fibers are interwoven to form a glass fabric. This glass fiber weave is partially dried to form a B-stage material. All prepregs are B-stage materials. During the manufacturing process of prepreg, it is important to follow the grain direction of the material being used since it allows the material to be modified as per requirement. The number of warp and fill counts determines the amount of resin the glass fabric can retain.

How to choose prepreg in PCB design and fabrication?

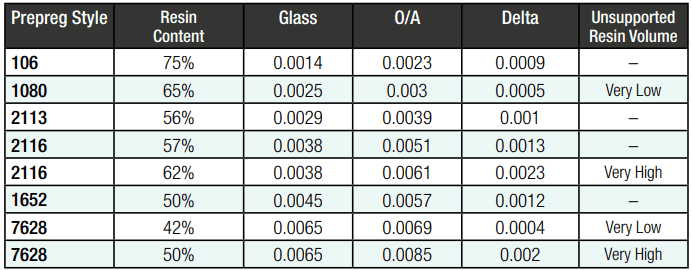

There are different types of prepregs that are incorporated in PCBs depending on the thickness and other requirements. Prepregs are available in Standard Resin (SR), Medium Resin (MR), and High Resin (HR) depending on the resin content they hold. The more resin content they hold, the more expensive they get. Here’s a table for your better understanding:

How is resin content in prepreg and laminates measured?

Resin content is the ratio of the resin used in the prepreg to the overall weight of the prepreg. The method to test the resin content in the prepreg is as follows:

- Take a prepreg sample/specimen and measure the initial weight.

- Next, dip the specimen in LR grade sulphuric acid (H2SO4) for a few seconds for all the resin to be dissolved in the acid.

- Rinse the specimen with water and dry it.

- Now, measure the weight of the specimen. The difference in weight will give you the amount of resin for a given quantity of the specimen.

Resin (%) = Loss of Weight of Specimen/Original Weight of Specimen x 100

Resin content decides how thick a piece of laminate will be when it is pressed. The content also has considerable effects on properties such as the dielectric constant, Coefficient of Thermal Expansion (CTE), and drilling and etching quality.

Design for Manufacturing Handbook

10 Chapters - 40 Pages - 45 Minute ReadWhat's Inside:

- Annular rings: avoid drill breakouts

- Vias: optimize your design

- Trace width and space: follow the best practices

- Solder mask and silkscreen: get the must-knows

Download Now

What is resin flow in prepreg?

When you heat prepreg under pressure the resin melts (liquefies) and flows. This is called resin flow. The pressure and the rate at which the resin heats up affects the amount of flow that occurs. There is a limited period of time during which the resin remains fluid enough to flow freely, after which we say it has gelled. This is the basic principle behind the lamination process.

The actual flow of the resin is critical to the lamination operation and can be significantly impacted by laminating conditions. The amount of actual flow present will affect such properties as the interlaminar bond, bond to oxide inner layer copper foil, bond of laminate to ED copper foil utilized in laminate manufacture. It also affects the overall effectiveness of prepreg as a bonding sheet. Check out our article lamination voids and delamination in PCB manufacturing to study the effects of voids.

What is the difference between prepreg and core?

People often get confused between prepregs and cores due to their similarities. Allow me to clarify it for you. The core is a product of prepreg and lamination. It is more rigid compared to the prepreg. The core is made up of a fiberglass-epoxy laminate which meets the FR4 (Flame Retardant) grade with copper on either side. The core is usually manufactured by a core manufacturer and the company is liable for any faults in the material that might hinder the operation of a PCB. Whereas prepregs, as described earlier, are also made of the same material like the core but are partially dried without lamination and aren’t rigid like the core.

Another major difference between the prepreg and the core when used in stack up is the dielectric constant (Dk ). The Dk for the core does not vary, whereas the prepreg Dk before and after lamination will vary. This is why a few military applications of PCBs don’t use the foil method, instead go for the core method of lamination. I hope this disposes of the ambiguity.

Now, the thickness of the PCB depends on the type of prepregs used. It must be noted that the required thickness can be achieved by a combination of prepreg plies. If you are wondering what plies are, they are nothing but thin sheets of prepregs placed on top of one another. This helps in achieving the desired thickness of the PCB.

Other than PCBs, prepregs find their applications in aerospace components, automotive parts, A/C ducting, machinery, tooling, honeycomb and foam panels, and many more.

The difference between prepreg and laminate

| Feature | Prepreg | Laminate |

|---|---|---|

| Definition | Partially or uncured core material | Fully cured core material |

| Usage | Used to bond two copper layers together or to bind one copper layer and a core while retaining separation between the two materials being bonded. | Dielectric material with copper on one or both sides used for isolation between copper layers |

| Stackup location | It is located between two cores or between a core and copper foil. | It is located between copper layers or planes. It may also form the core of the board stackup. |

Prepregs are insulators that glue together cores and copper foils and assist in the manufacture of a robust PCB. Prepregs are at the heart of every PCB and knowledge of prepreg material is critical to PCB fabrication. A manufacturer will have to master the science of prepregs to create boards that function according to specifications.