Related Categories — PCB Assembly

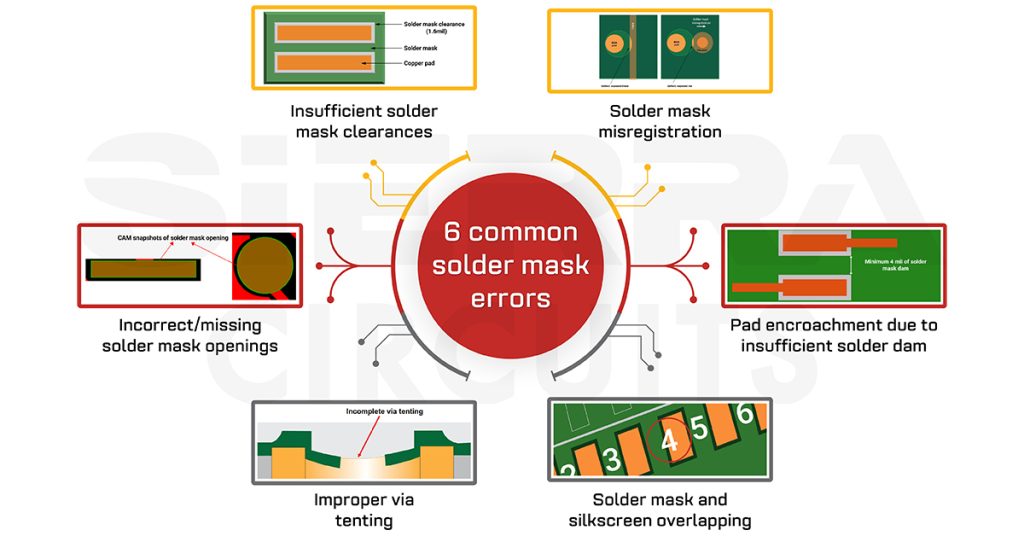

6 Common Solder Mask Errors Every PCB Designer Should Know

A solder mask is an insulation layer that covers conductive areas such as traces and pads. Inappropriate solder layer application […]

PCB Design

Case Study: Routing Microcontroller and BGA in Rigid-Flex PCBs

When routing microcontrollers and BGAs, you need to consider the trace spacing requirements of your design and clearance ... more »

Case Studies

Advantages of Ordering PCB Prototype and Bulk Production from a Single Fab House

Choosing the same fab house for PCB prototypes and bulk production has many advantages, such as better DFM ... more »

PCB Manufacturing

6 Common Solder Mask Errors Every PCB Designer Should Know

A solder mask is an insulation layer that covers conductive areas such as traces and pads. Inappropriate solder ... more »

PCB Design

Case Study: Routing Microcontroller and BGA in Rigid-Flex PCBs

When routing microcontrollers and BGAs, you need to consider the trace spacing requirements of your design and clearance ... more »

Case Studies

Advantages of Ordering PCB Prototype and Bulk Production from a Single Fab House

Choosing the same fab house for PCB prototypes and bulk production has many advantages, such as better DFM ... more »

PCB Manufacturing

How to Design and Build a Hybrid PCB Stackup

A hybrid stackup construction enhances your PCB’s performance and cost-effectiveness by combining different materials or technologies. It helps ... more »

PCB Manufacturing

Case Study: Eliminating BOM and Footprint Errors in PCB Assembly

Sticking to DFA benchmarks ensures components are correctly assembled on a PCB without any discrepancies. DFA brings down ... more »

Case Studies

Case Study: Designing 8 and 14-Layer HDI PCBs with Stacked Vias

Stacked vias are considered the most suitable solution for manufacturing HDI boards with advanced features. The configuration, with ... more »

Case Studies

How Sequential Lamination is Performed to Manufacture HDI PCBs

Sequential lamination is a process of fabricating a circuit board using subsets composed of copper and dielectric layers. ... more »

HDI / Blind & Buried Vias

Case Study: Designing an HDI Board with 0.4 and 0.65 mm BGAs

BGA technology makes it possible to achieve a smaller form factor in PCBs. With a higher pin count, ... more »

Case Studies

How to Optimize Your PCB Trace Using IPC-2152 Standard

IPC-2152 is the standard for determining the current capacity, temperature rise, and width of a trace in a ... more »

IPC

Fabrication, Procurement, & Assembly. PCBs fully assembled in as fast as 5 days.

- Bundled together in an entirely-online process

- Reviewed and tested by Engineers

- DFA & DFM Checks on every order

- Shipped from Silicon Valley in as fast as 5 days

Fabrication. Procurement & Assembly optional. Flexible and transparent for advanced creators.

- Rigid PCBs, built to IPC-6012 Class 2 Specs

- 2 mil (0.002″) trace / space

- DFM Checks on every order

- 24-hour turn-times available

Complex technology, with a dedicated CAM Engineer. Stack-up assistance included.

- Complex PCB requirements

- Mil-Spec & Class 3 with HDI Features

- Blind & Buried Vias

- Flex & Rigid-Flex boards