Related Categories — Flex PCBs

5 Factors That Delay Flex PCB Quick Turn Delivery

The production of flex circuit boards is rising at a rapid rate in response to the increased demand. Quick turn flex PCBs are in high demand and are put into production as soon as they are tested. Incomplete data sets and designs with technical issues are among the major obstacles that delay the quick turn lead time.

Design Guidelines

DFM for Flex and Rigid-Flex PCBs Utilizing SMT

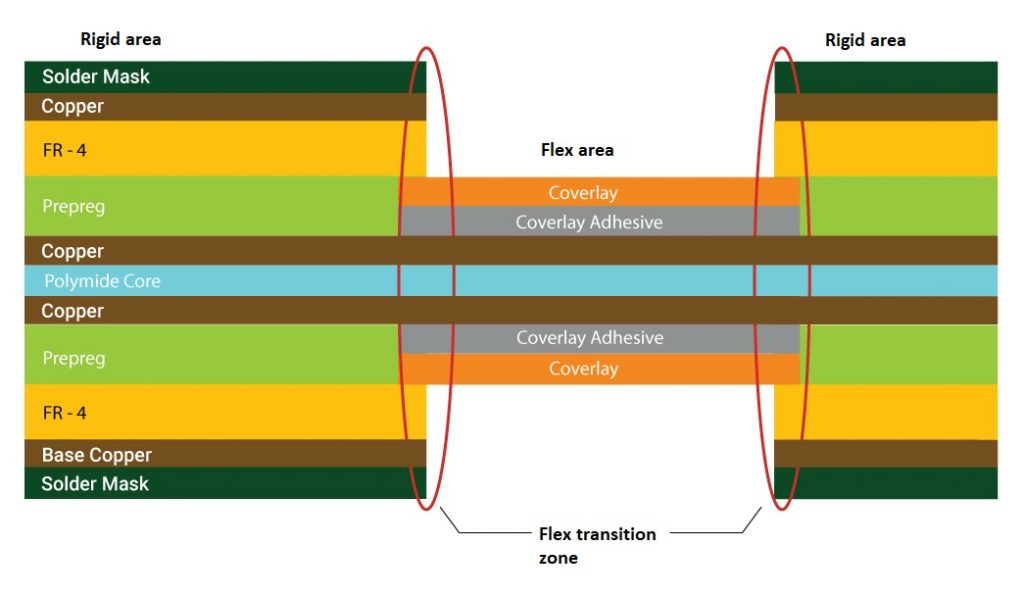

Design for manufacturing (DFM) guidelines resolve potential issues that can occur during the manufacturing and assembly of circuit ... more »

Flex PCBs

Choosing Smaller Footprints for HDI Design

The main agenda of using HDI technology is to pack more components on a smaller board. Choosing smaller ... more »

HDI / Blind & Buried Vias

5 Factors That Delay Flex PCB Quick Turn Delivery

The production of flex circuit boards is rising at a rapid rate in response to the increased demand. ... more »

Design Guidelines

DFM for Flex and Rigid-Flex PCBs Utilizing SMT

Design for manufacturing (DFM) guidelines resolve potential issues that can occur during the manufacturing and assembly of circuit ... more »

Flex PCBs

Choosing Smaller Footprints for HDI Design

The main agenda of using HDI technology is to pack more components on a smaller board. Choosing smaller ... more »

HDI / Blind & Buried Vias

Handling Differential Signaling in Flex PCBs

Most modern devices employ differential signaling to meet high-speed and high data-rate needs. Controlling differential signaling in rigid ... more »

Controlled Impedance

Key Aspects of DFM for HDI PCBs

Design for manufacturability (DFM) for HDI PCBs refers to designing layouts that reduce the errors associated with fabrication ... more »

Defense & Space

Top 6 Missing Information When Requesting a PCB Quote

Once a circuit board designer prepares the design, the next step is to find a manufacturer to transform ... more »

PCB Assembly

Impedance Matching in HDI PCB Design

Impedance matching is the way of configuring the input impedance of a load or the output impedance of ... more »

Controlled Impedance

What Are the Cost Drivers of Flex PCBs?

Cost optimization is one of the major objectives when designing a PCB. To achieve that, every designer should ... more »

Flex PCBs

Making Sense of Wave Soldering

Depending on component technology, many options exist for automated mass soldering today. But wave soldering was the first ... more »

PCB Assembly

Fabrication, Procurement, & Assembly. PCBs fully assembled in as fast as 5 days.

- Bundled together in an entirely-online process

- Reviewed and tested by Engineers

- DFA & DFM Checks on every order

- Shipped from Silicon Valley in as fast as 5 days

Fabrication. Procurement & Assembly optional. Flexible and transparent for advanced creators.

- Rigid PCBs, built to IPC-6012 Class 2 Specs

- 2 mil (0.002″) trace / space

- DFM Checks on every order

- 24-hour turn-times available

Complex technology, with a dedicated CAM Engineer. Stack-up assistance included.

- Complex PCB requirements

- Mil-Spec & Class 3 with HDI Features

- Blind & Buried Vias

- Flex & Rigid-Flex boards