Related Categories — Controlled Impedance » PCB Design » PCB Technologies

How to Control your Controlled Impedance

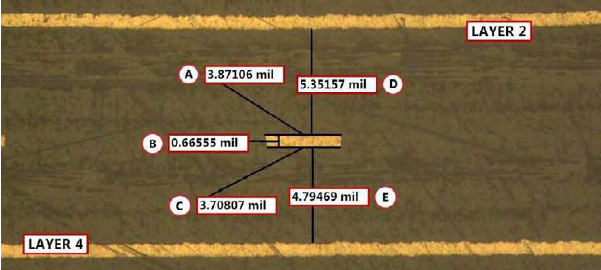

While manufacturing a PCB, controlled impedance can be achieved through specific dielectric thickness and by providing the target ohms on each layer. The factors that influence impedance are the PCB materials’ dielectric, the trace thickness, width, and height from the ground plane.

Controlled Impedance

Why Controlled Impedance Really Matters

Every day, PCB designs and components become smaller, faster – in other words, more complicated. It is now ... more »

Controlled Impedance

9 Factors that Lead to Signal Integrity Issues in a PCB

Avoiding signal integrity issues in a PCB is an extremely complex task for designers. It requires a deep ... more »

Controlled Impedance

How to Control your Controlled Impedance

While manufacturing a PCB, controlled impedance can be achieved through specific dielectric thickness and by providing the target ... more »

Controlled Impedance

Why Controlled Impedance Really Matters

Every day, PCB designs and components become smaller, faster – in other words, more complicated. It is now ... more »

Controlled Impedance

9 Factors that Lead to Signal Integrity Issues in a PCB

Avoiding signal integrity issues in a PCB is an extremely complex task for designers. It requires a deep ... more »

Controlled Impedance

Measuring PCB, Cable and Interconnect Impedance, Dielectric Constant, Velocity Factor, and Lengths

Controlled impedance PCBs often include a measurement “coupon”, which typically includes sample traces, 6 inches long and constructed ... more »

Controlled Impedance

Fabrication, Procurement, & Assembly. PCBs fully assembled in as fast as 5 days.

- Bundled together in an entirely-online process

- Reviewed and tested by Engineers

- DFA & DFM Checks on every order

- Shipped from Silicon Valley in as fast as 5 days

Fabrication. Procurement & Assembly optional. Flexible and transparent for advanced creators.

- Rigid PCBs, built to IPC-6012 Class 2 Specs

- 2 mil (0.002″) trace / space

- DFM Checks on every order

- 24-hour turn-times available

Complex technology, with a dedicated CAM Engineer. Stack-up assistance included.

- Complex PCB requirements

- Mil-Spec & Class 3 with HDI Features

- Blind & Buried Vias

- Flex & Rigid-Flex boards