Contents

On-demand webinar

How Good is My Shield? An Introduction to Transfer Impedance and Shielding Effectiveness

by Karen Burnham

Look up! It’s a bird, it’s a plane, it’s a superhero! No, it’s a drone about to make a pitstop at Birdstop!

Humankind has revolutionized every field of science, building inseparable bonds between sentience and automation. Of all fields, flight has always captured our imagination. At the beginning of the 20th century, two brothers building bicycles took humanity into the skies for the first time, setting off an explosion in aviation technology. Within a mere few generations, the skies have become dotted with human presence. Today, a human no longer needs to be in the cockpit for an aircraft to fly. The recent decade has seen a huge surge in Unmanned Aerial Vehicles (UAV) or Unmanned Aircraft Systems (UAS), colloquially known as drones.

Aerial Robots

Drones are essentially flying robots that unlock easy movement in 3-dimensional space. They are either remotely controlled or can fly autonomously through software determined flight plans in coordination with sensors and GPS.

As with many aviation technologies, UAVs were originally popularized by military applications. However, in recent years their non-military use cases have really been where the growth has been. UAVs are rapidly finding their way into applications like industrial inspection, logistics, precision agriculture, law enforcement, and more.

Drones and PCBs

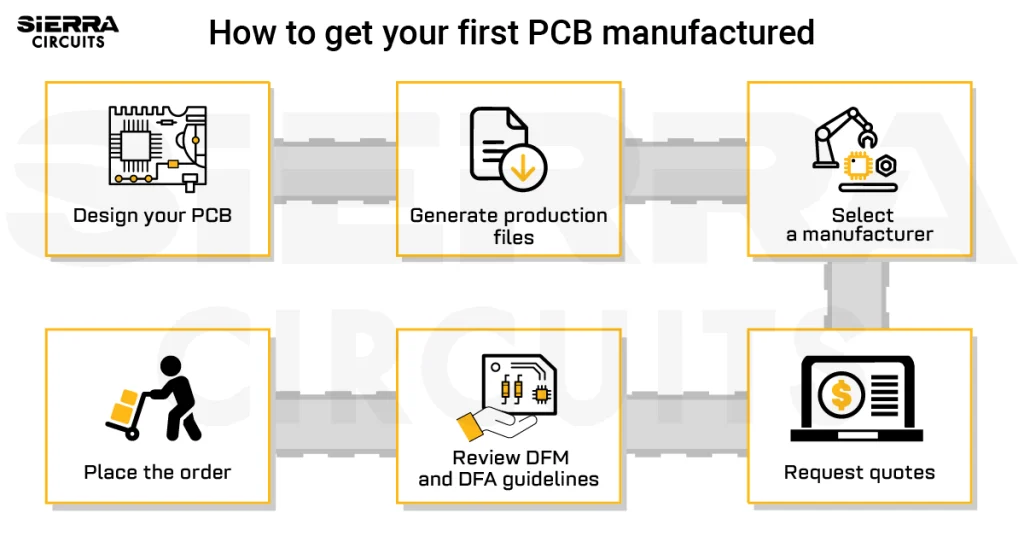

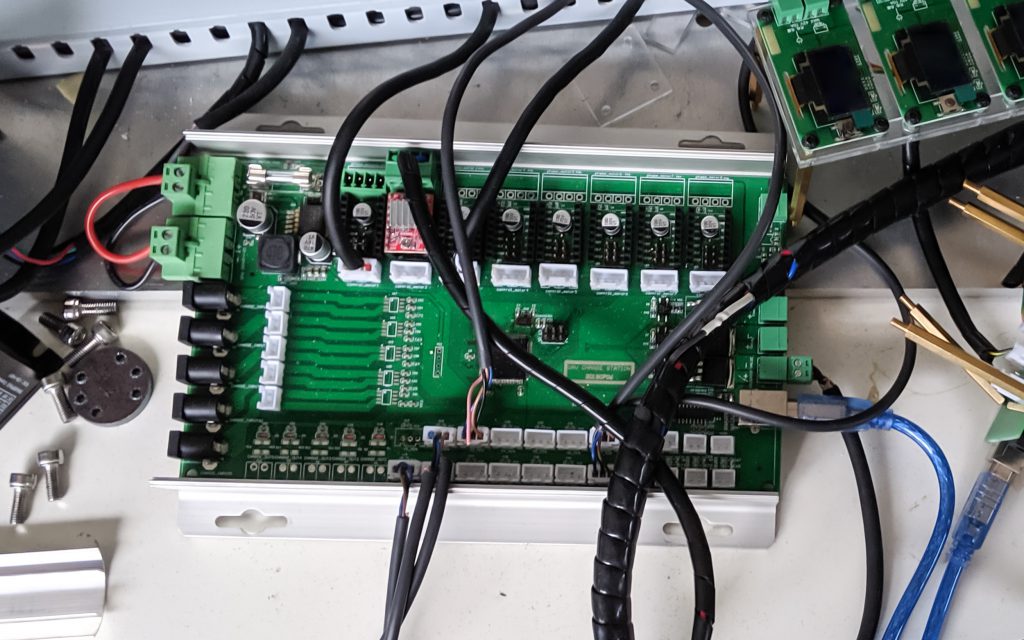

Unsurprisingly, Printed Circuit Boards (PCBs) have major application in the drone industry. For instance, the increased functionality in state-of-the-art PCBs have enabled he reduction in weight and increase in functionality of today’s UAVs. The PCBs used in drone technology are rugged and can withstand adverse environmental conditions. Similarly, the PCBs used in Birdstop docking stations are designed from the ground up to be performant and reliable under repetitive field deployment.

Birdstop: A Unique Automation Solution

For all the wonders of unmanned aircraft, they are still ironically very human dependent. Today, operators often spend more time bringing a UAV to and from the location it is needed than on the actual flight itself. This is because UAVs have no means of subsisting permanently in the field, be it a plantation or an oilfield. For starters, the vast majority of commercial UAVs last no more than 20-30 minutes in the air, requiring a human on the ground ready to make a swap.

While human intervention is fine, or even desired, for recreational purposes, the human dependency critically hampers commercial uses that require repeated data collection in off-the-beaten path remote locations.

That’s where Birdstop comes in. By permanently placing a Birdstop docking station out in the field, drones no longer need a human present to operate. The docking station takes care of everything a human operator would do, including launching, landing, battery exchange, battery charging, and data transmission. It all closes up in a compact, rugged, weatherproof hangar to protect the drone until next needed.

Birdstop’s Focus: Industrials and Agriculture

Annually, an estimated $50 billion is spent in energy industry inspections. An additional $30 billion is spent in agriculture. The manual inspection methods used today have proven to be dangerous and inefficient, with inspectors going into the middle of nowhere on a repeated basis. In some sub-sectors, industrial inspectors face occupational hazards and fatality rates twice that of police and firefighters Birdstop allows assets and fields to be thoroughly looked at and analyzed with humans in the office, not in the field.

Birdstop CEO Keith Miao described the value proposition of the system as “drastically lowering the cost of local data collection for industrial and agricultural clients”. The product is like a pitstop for drones, turning them into Roomba-like tools that are operated repetitively by themselves.

Some have also made the comparison between Birdstop powered drones and satellites – instead of circling the globe, the drone circles a localized asset.

Behind the Scenes

Since its inception in 2018, Birdstop has been part of the Verizon 5G Lab startup program in Palo Alto. Situated just down the hall from the latest in 5G equipment, Birdstop has been immersed in technology support and mentorship from the best in Telecom. In 2019, Birdstop won 1st place at the 5G Lab startup competition for its cohort.

Birdstop is led by its CEO and inventor Keith Miao, a former technology manager at Google. The idea of Birdstop took root a decade earlier, when Keith was a student at Columbia University’s Earth Institute, analyzing agricultural field data and imagery. Over the years, Keith discovered how many industries routinely dispatch humans into remote locations to look at something. In 2016, when the regulation for Beyond Visual Line of Sight (BVLOS) drone operations moved forward, Keith saw an imminent solution for a much better way to “look at something”. The Birdstop team today draws expertise from Google, Tesla, and NASA with advisors across Industrials and Agriculture.