Contents

On-demand webinar

How Good is My Shield? An Introduction to Transfer Impedance and Shielding Effectiveness

by Karen Burnham

Electronic devices are shrinking in size and increasing in complexity due to improvements in VLSI technology. The need for more interfacing input/output (I/O) leads and smaller device sizes have increased and this need can be met with the BGA (Ball Grid Array) package. BGA ICs having 4 pins to more than 500 IO’s are commonly available. Such BGA ICs have a smaller form factor and help decrease the size of circuits. This enables the design and manufacture of compact products.

BGA devices are used extensively in modern products such as mobiles, PCs, and various communication devices.

In this article, we discuss the following,

- What is BGA and PoP package?

- Features of BGA

- Types of BGA

- How the BGA is soldered to a PCB

What is a BGA?

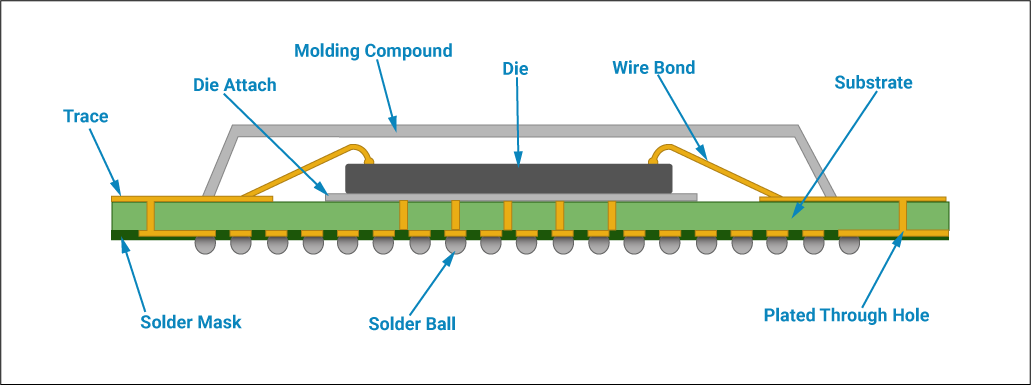

A Ball Grid Array Integrated Circuit is a surface mount device (SMD) component that possesses no leads. This SMD package employs an array of metal spheres that are made of solder called the solder balls for connections to the PCB (Printed Circuit Board). These solder balls are affixed to a laminated substrate at the bottom of the package.

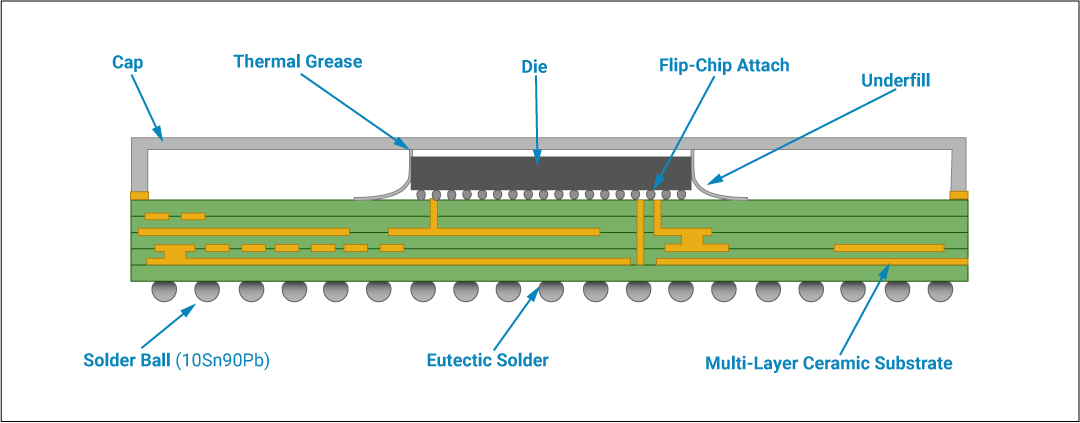

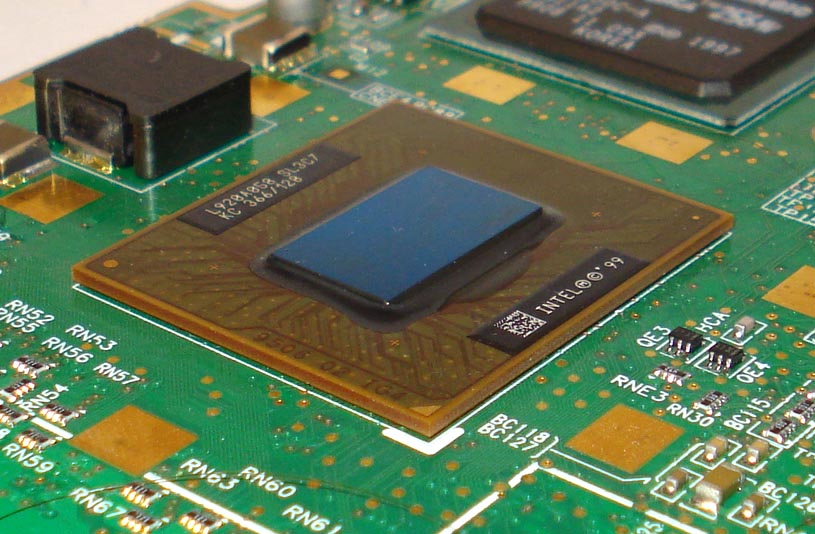

Figure (1) and Figure (2) display two examples of how BGA devices are constructed. Figure (1) shows how the BGA die/chip is mounted on the substrate and connected to the substrate by wire bonding technology. Figure (2) displays how the BGA die is connected to the substrate using flip-chip technology.

The BGA die connections are routed to the solder balls using metal traces on the substrate. BGA packages can provide more IO connections compared to dual in-line or flat packages.

The connections from the die to the balls in BGA ICs are on average shorter than perimeter-only type connections such as DIP ICs. Thus, leading to better performance at high speeds.

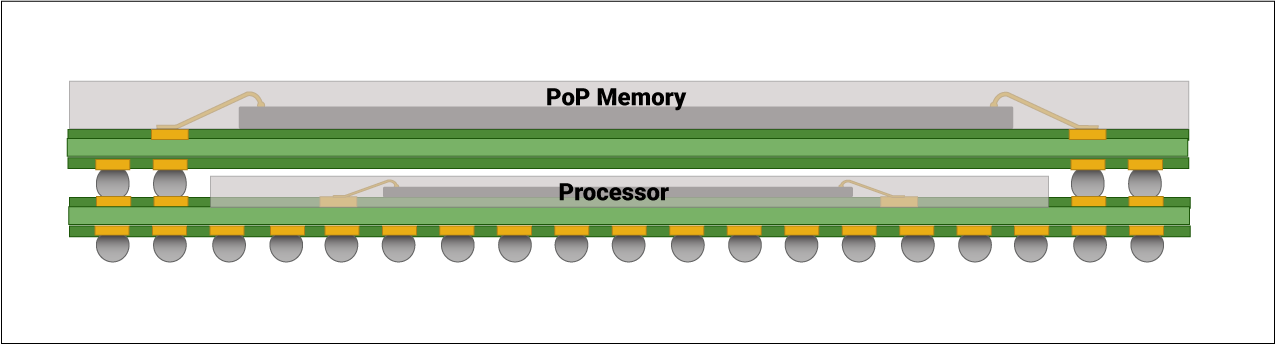

BGA PoP package

PoP is an acronym for package on package. It’s a process of stacking components or ICs together. PoP allows multiple ICs to be integrated into a single package such as a logic device or memory to be packaged with a processor. This greatly reduces the requirement for PCB area and minimizes signal integrity issues on the board. Finally, it helps to improve overall board performance at an additional cost.

Advantages:

- Reducing component size

- Minimizing overall cost

- Reducing board complexity

Of all the packages, the BGA is the most popular package used in high I/O devices in the industry.

Features of BGA

- High lead count

- No leads to bend

- High interconnection density

- Occupies lesser space on the board

- Low inductance

- Self-centering during the reflow process which reduces placement problems during surface mount soldering

- Lower thermal resistance between the package and the PCB. This allows heat generated by the integrated circuit inside the package to flow more easily to the PCB, preventing the chip from overheating

Learn how to breakout a .4mm BGA.

Types of BGAs

There is a wide variety of BGA device packages available in the market. Here are a few popularly used BGAs:

- Plastic over-molded BGAs (PBGAs) (Ball pitch 1.0mm, 1.27mm) – are an alternative form of the standard BGA. These BGA incorporate a plastic-coated body, a glass-mixture laminated substrate, and etched copper traces. PBGAs feature improved temperature stability and preformed solder balls

- High thermal metal top BGAs with low profile (HLPBGAs)

- Flex Tape BGAs (TBGAs)

- High thermal BGAs ( H-PBGAs)

One important point PCB designers need to follow, is to have the correct footprint pattern for the BGA device. This is because once the BGA is soldered it is very difficult to find any shorting or soldering problems. Also, investigating and fixing such problems involve high cost. Hence adequate care must be taken to design the PCB footprint pad. The footprint pattern design and routing pattern strategy are dependent on the pitch of the BGA device pins/balls. The table given below lists the different pitches available in BGA packages.

| BGA pins ball | Pitch in mm | Signal layer counts | |

| 2 trace | 1 trace | ||

| 256 | 1 | 2 | 3 |

| 324 | 0.8 | 2 | 3 |

| 484 | 0.8 | 3 | 4 |

| 484 | 1 | 2 | 4 |

| 625 | 0.8 | 3 | 4 |

| 676 | 1 | 3 | 5 |

| 784 | 0.8 | 4 | 5 |

| 900 | 1 | 3 | 5 |

| 1156 | 1 | 3 | 6 |

| 1517 | 1 | 4 | 7 |

| 1760 | 1 | 4 | 8 |

| 1924 | 1 | 4 | 8 |

| 2577 | 1 | 5 | 9 |

| 2892 | 1 | 5 | 10 |

Learn How To Breakout a .5mm BGA

How the BGA is soldered to a PCB

The BGA soldering technique

In the PCB assembly process, the BGA is soldered on to the circuit board by the solder reflow process, using a reflow oven. During this process, the solder balls melt in the reflow oven.

Precautions to ensure good soldering technique

- Sufficient heat must be applied to ensure that all the balls in the grid melt sufficiently for every BGA solder joint to establish a strong bond.

- The surface tension of the molten balls helps hold the package in place on the PCB until the solder cools and solidifies. An optimum temperature controlled BGA soldering process is necessary for solid solder joints and also to prevent solder balls from short-circuiting each other.

- The composition of the solder alloy and soldering temperature are precisely chosen so that the solder doesn’t completely melt but stay semi-liquid, allowing each ball to stay separate from its neighbors.

BGA Solder Joint inspection

Optical techniques cannot be used to inspect BGAs since the solder joints are hidden from sight beneath the BGA components. Also, electrical tests aren’t very reliable since the tests reveal the electrical conductivity of the BGA at that particular instant. This test doesn’t predict if the solder will last long enough. The solder joint may in fact fail over a period of time.

X-ray inspection for BGA

The BGA solder joint bonds are inspected using X-rays. The X-ray inspection helps to look through the device solder joint underneath the components. Due to this ability, the Automated X-ray Inspection (AXI) technology is widely used for BGA inspection.

There are many types of inspection tests available such as manual, AOI, ICT, functional tests, etc. Refer to our post on the PCB assembly inspection report format to get a thorough understanding of all these tests.

Removing faulty BGAs (BGA rework)

If the BGA components are found to be faulty, then they are carefully detached from the board by melting the solder joint. This is done by locally heating the BGA component until the solder joint melts underneath it. In the rework process, the component is heated in a dedicated rework station. This consists of an infrared heater, a thermocouple that monitors the temperature, and a vacuum device to raise the package. You must ensure with great precaution, that only the faulty BGA component is heated without damaging the neighboring components on the board.

Learn How HDI Boards Can Be More Economical

BGA components are well established in the electronics industry for their numerous advantages, in both mass production and prototyping. As the component count increases on the PCB, the routability and component placement get complex. This complexity of component density can be better managed with BGA packages. BGA devices are increasingly used in the industry and have the advantage of having higher IO counts in lesser space and therefore are suitable for complex and compact electronics design.