Contents

On-demand webinar

How Good is My Shield? An Introduction to Transfer Impedance and Shielding Effectiveness

by Karen Burnham

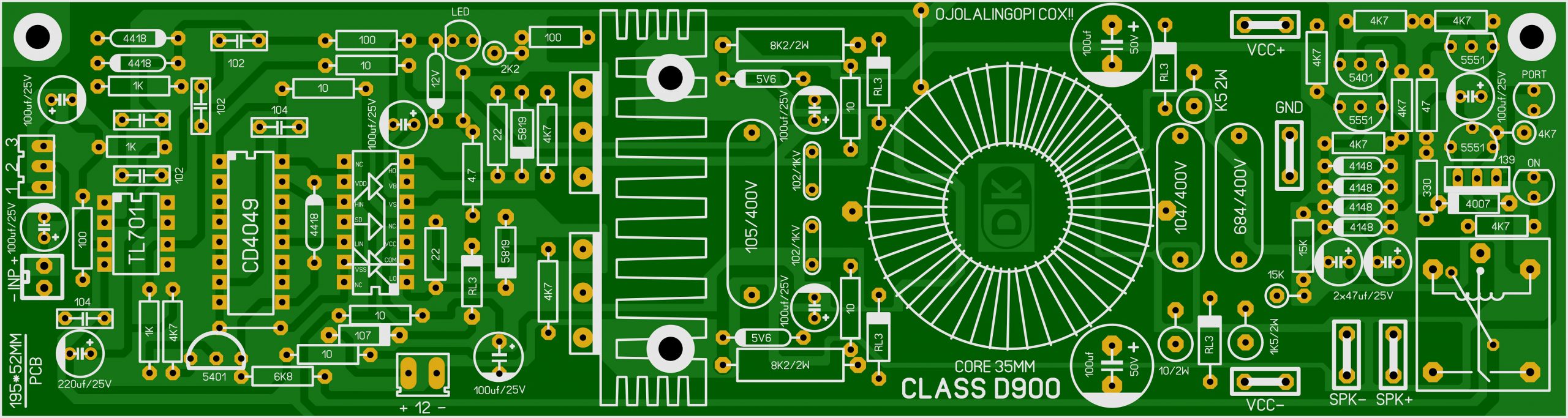

Once a circuit board designer prepares the design, the next step is to find a manufacturer to transform it into a finished product. To get the board manufactured, an estimate or a PCB quote needs to be placed. The main intention is to fabricate and assemble a board with minimum cost and process steps.

A manufacturer can give an accurate quote only if the PCB designer provides all the vital information associated with that particular board. Let us have a look at the essential information that is often missed while requesting a quote.

What is a PCB quote?

A PCB quote is a general estimate that describes the time, cost, and capabilities of a manufacturer to convert the submitted design into a physical board. It is not necessarily related to the board fabrication alone. A quote can be requested for information related to PCB design, manufacturing, or assembly.

What is a prototype board quote?

Most contract manufacturers’ (CM) websites have sections for requesting a prototype board quote. This provides an option to get the information for prototype PCBs. These types of boards are built to check whether the concept/design is functional or not.

Normally, prototyping is done with a shorter schedule and quicker turnarounds. The quantities produced during prototyping are generally 5-10.

How to get an accurate PCB quote

A quote from a CM is not just a piece of information stating the cost for the required number of circuit boards, but it also gives an idea about the time requirements and capabilities of the fabricator to include all the technologies involved in the board design.

The accuracy of the quote eases the manufacturing process. To make the process faster with no delays, it is better to include all the necessary details in one go. If any important information is missing, then the CM will have to contact the designer.

While this communication is in progress, the order will go on hold. If an order is kept on hold for too long, it might miss some internal manufacturing deadlines. As a result, the production may take a longer time than estimated.

The critical information required for an accurate quote is given below:

- Type of board (rigid, flex and rigid-flex, etc.)

- Number of board layers

- Individual board dimensions

- Material

- Minimum hole size

- Number of holes

- Minimum trace width

- Minimum space between traces

- Outer layer copper finish

- Annular ring requirements

How to create a circuit board design quote

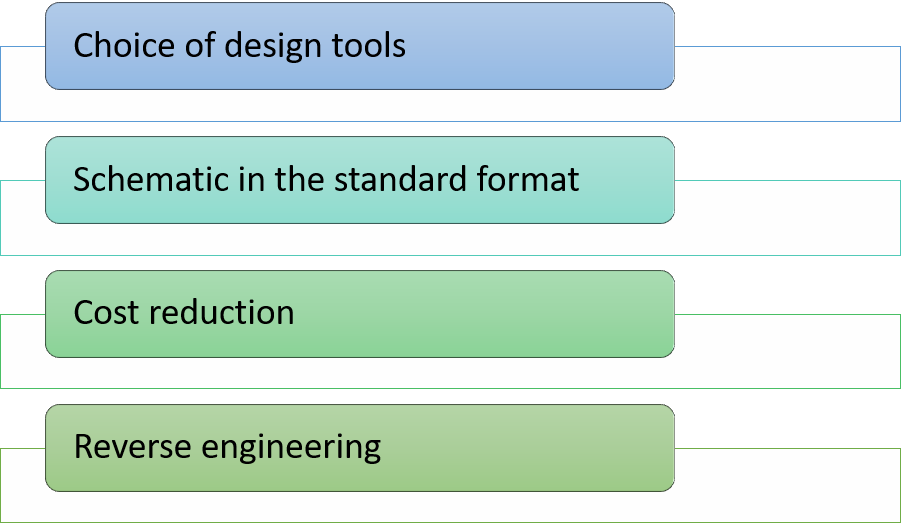

A quote for PCB design (schematic and layout) is raised when the requestor does not have the capabilities to design a layout or has insufficient resources.

Usually, the important files uploaded are BOM, schematic, board outline, and mechanical details (DXF files).

You have to write down the design needs as well. A design service quote will consist of the cost of PCB design and the estimated time frame.

From the design services, you can expect the following:

- Choice of design tools: CMs also provide wide options of design tools for the customer to choose from. The selected tool will be used for creating the schematic and all other design-related files.

Try our KiCad PCB plugin for instant quote creation. It validates the design data, provides cost estimates, and gets a quote without quitting KiCad UI.

- Schematic: While submitting the quote, any rough schematic can be added, and then the design team will convert it into the preferred CAD format.

- Cost reduction: The manufacturer will work around the submitted design and optimize it for cost reduction and process efficiency.

- Reverse engineering: Various CMs provide the option to create all the design files for a new PCB based on the details of an existing board as per the request. These details can be of a bare board, a populated board, or just mere design files or drawings. The designer has to specify the differences from the existing board, and accordingly, the new design files will be generated.

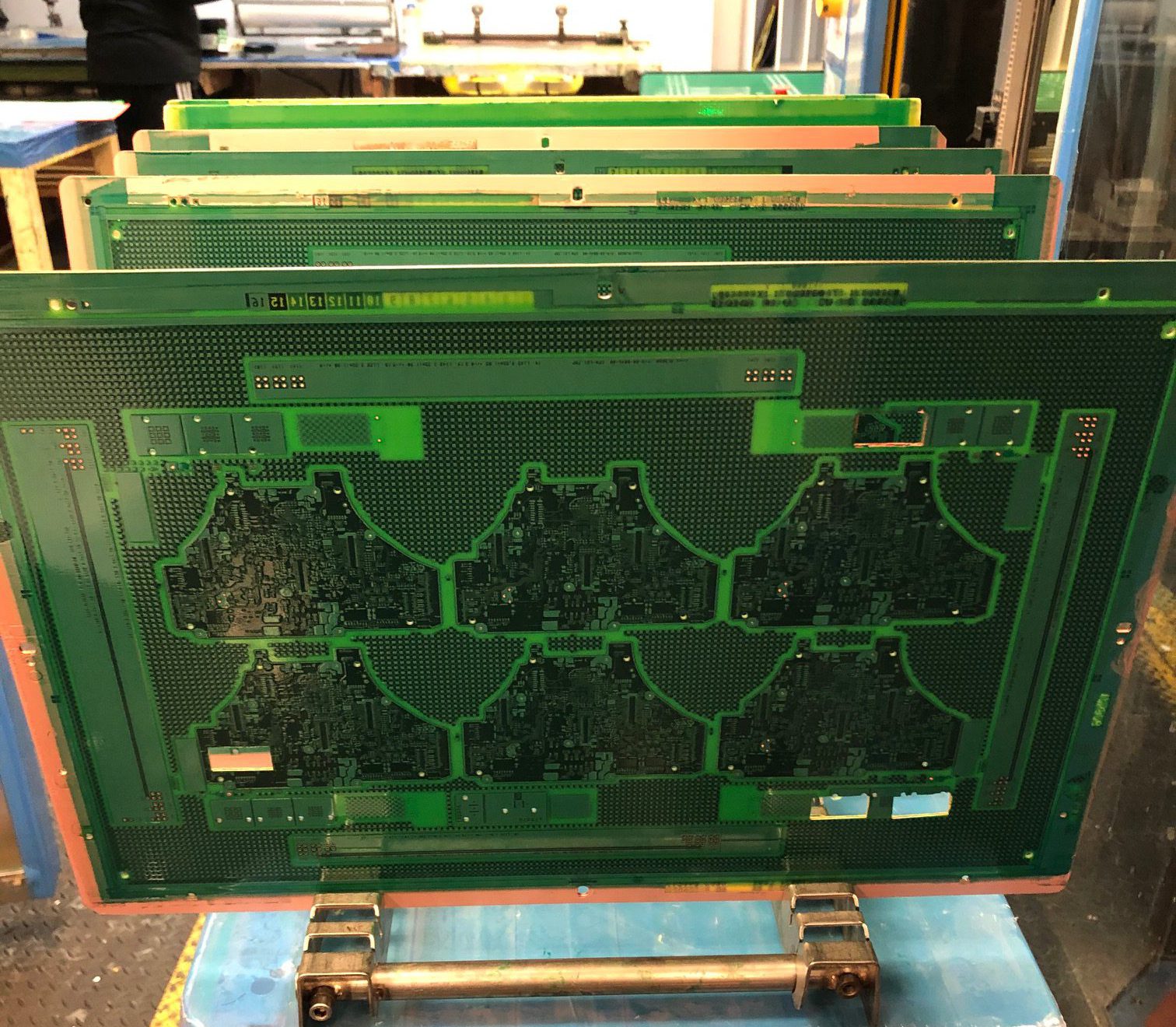

How to get a quote for PCB fabrication services

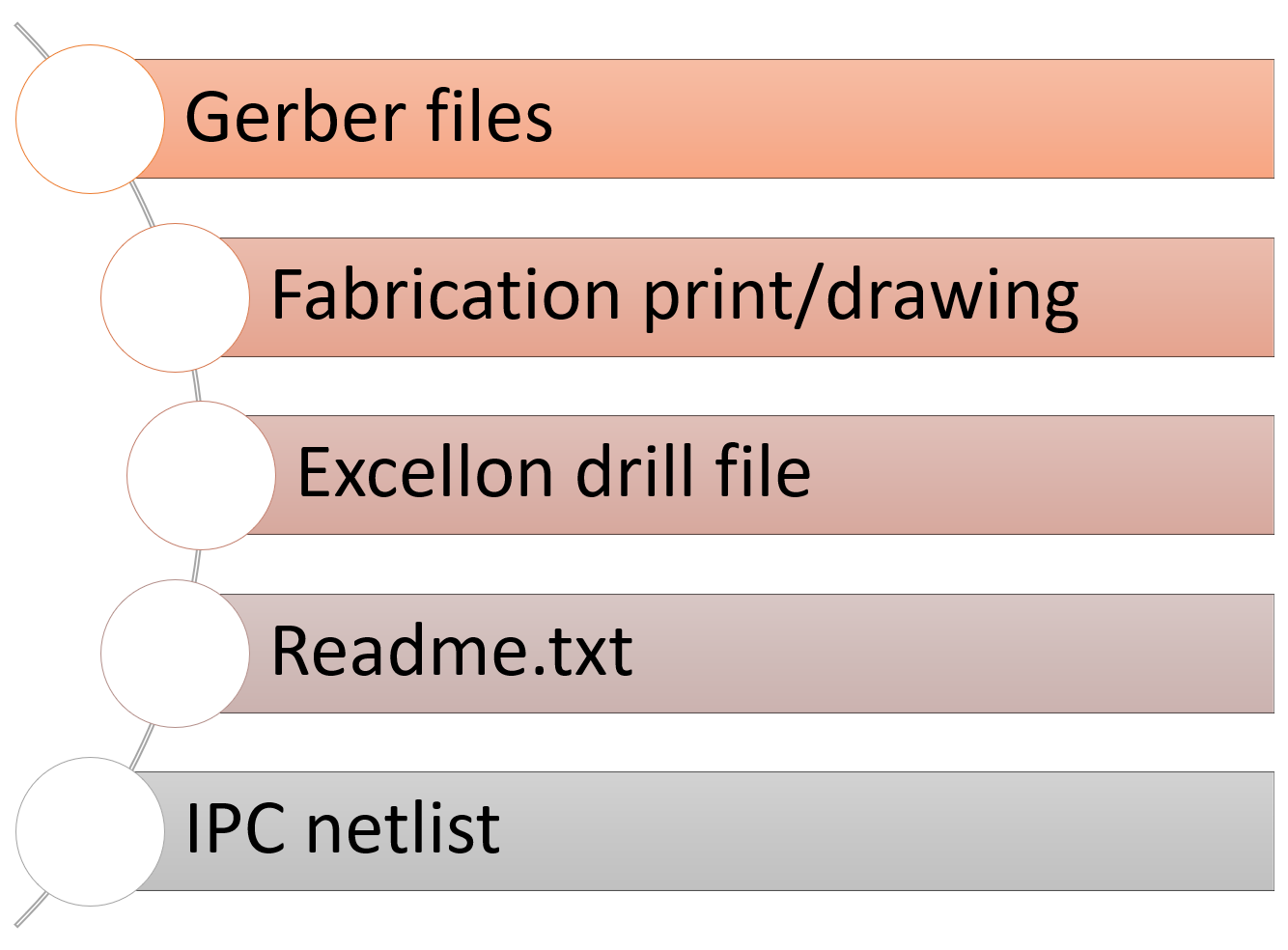

For a fabrication quote, the following files are crucial:

- Gerber files with English units in RS-274X format or ODB++ format. These files should be generated for each circuit board layer.

- Fabrication print/drawing (in Gerber format) that should include board outline, drill pattern, and hole sizes.

- Excellon drill file (ASCII format) with details such as units, tool units, coordinates, number format, and so on.

- Readme.txt file with board and file details, as well as layer stack-up information.

- IPC netlist illustrates the list of networks that establishes the conductivity interconnection scheme of a circuit board.

How to request a board assembly quote

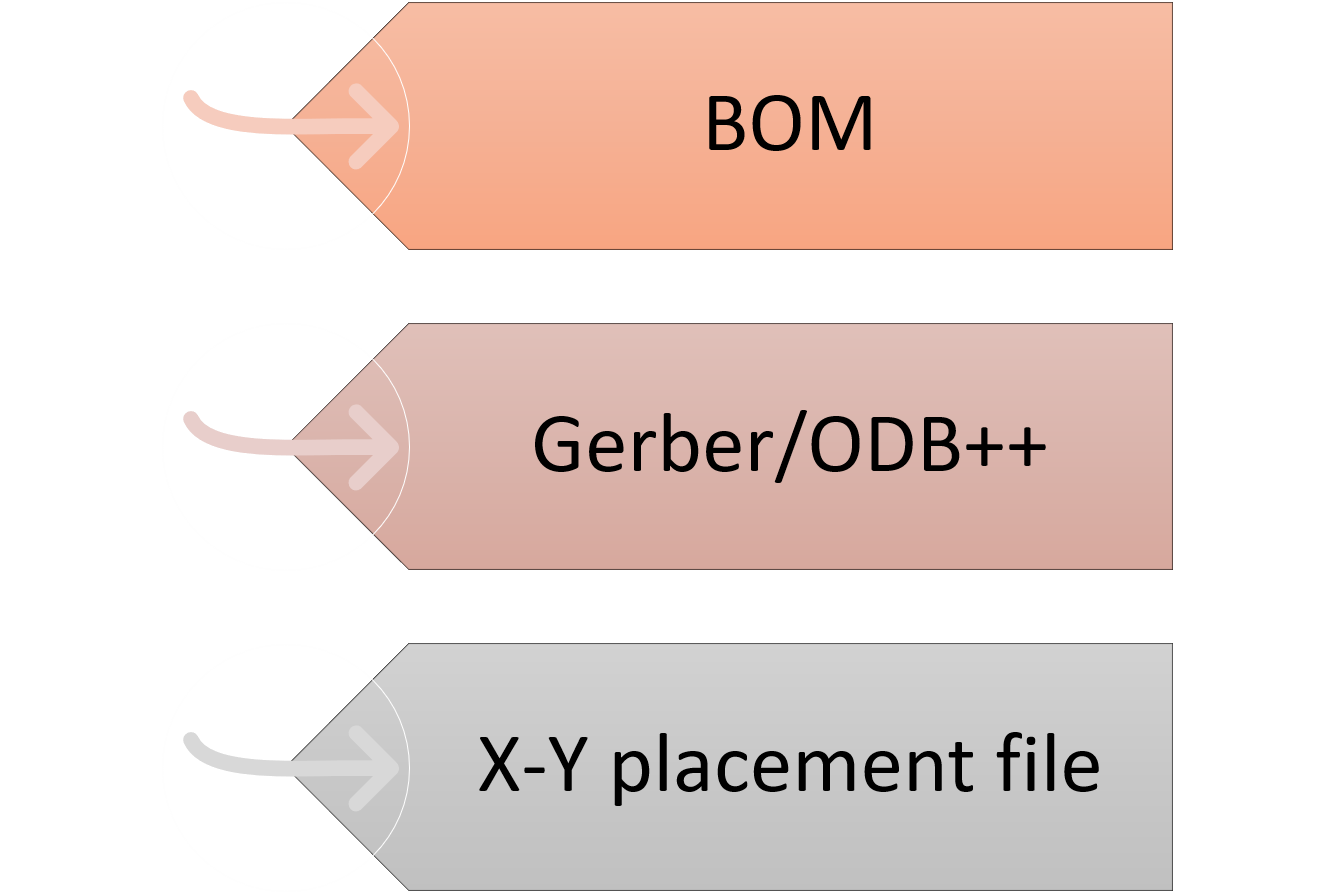

A PCBA quote generally requires the following assembly files:

- BOM file is necessary for a CM to understand and get an estimate about the pricing of components.

- Gerber/ODB++ file is essential for PCB manufacturing as well as assembly. It provides information regarding each and every layer of the board.

- An XY placement data file helps with component placement along with the assembly drawing.

Design for Assembly Handbook

6 Chapters - 50 Pages - 70 Minute ReadWhat's Inside:

- Recommended layout for components

- Common PCB assembly defects

- Factors that impact the cost of the PCB assembly, including:

- Component packages

- Board assembly volumes

Download Now

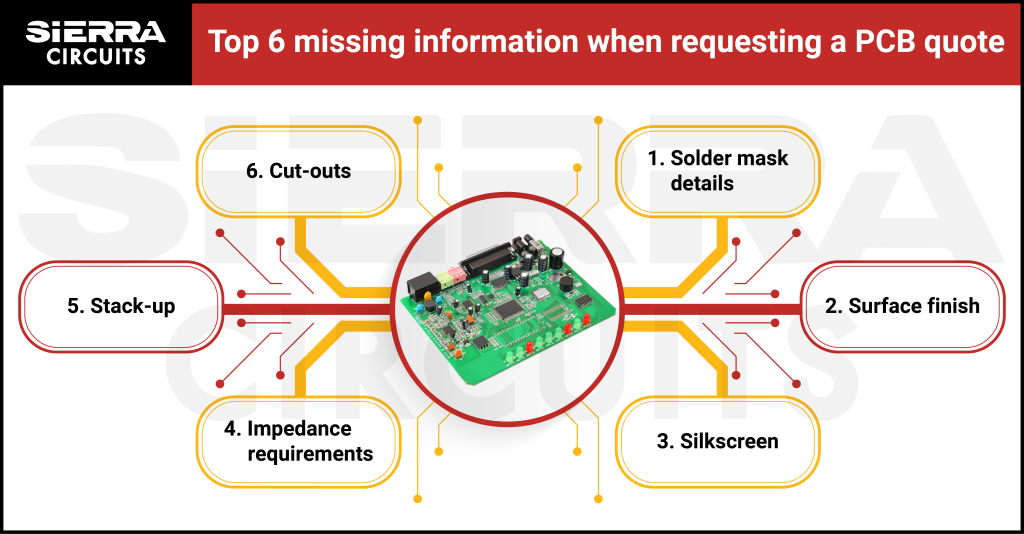

Top 6 frequently missed data during RFQ

While most designers carefully provide all the primary details discussed above, some may miss out on some secondary details. These details are also important for calculating the total cost and time estimate and should be submitted while raising a request for quote (RFQ).

The generally missed ones are given below:

1. Solder mask details

Apart from clicking ‘yes’ for the solder mask, there are some essential details that need to be shared with the CM. These details include:

- Solder mask sides (top, bottom, or top and bottom)

- Solder mask type (LPI – liquid photo-imageable)

- Solder mask color (green, blue, black, red, white, or clear)

- Solder mask finish (semi-gloss or matte)

2. Surface finish

The type of surface finish used on the board influences its operation. The commonly used surface finishes include hot air solder leveling (HASL), electroless nickel immersion gold plating (ENIG), electroless nickel electroless palladium immersion gold (ENEPIG), among others. Hence, if not properly specified, a wrong type of surface finish will negatively affect the PCB efficiency. This is an important detail that is often missed while requesting a quote.

3. Silkscreen

Another detail that is frequently overlooked is the silkscreen. Just like the solder mask, clicking ‘yes’ in the silkscreen option is not enough. Questions regarding whether it is needed on both sides and what color is required should also be answered.

4. Impedance details

The controlled impedance requirements of a circuit board determine the selection of various parameters. Therefore, if not provided, it will delay the quote.

5. Stack-up details

The number of layers, order of the layers, the thickness of each layer, the total thickness of the stack-up, etc., are details regarding the stack-up that should not be missed.

6. Cut-out

Any opening on the board not created by mechanical drilling is known as a cut-out. The dimensions and positions of the cut-out are also part of the information given to request a quote.

How to avoid delays in the circuit board quoting process

Sometimes, the PCB quotes for design, assembly, or manufacturing may get delayed by the manufacturer. There are some common reasons for this to happen:

- Corrupt or missing files

- Any of the following important information is missing from the fab drawing/print:

- Material type

- Finished board thickness

- Board outline and dimensions

- Cutouts/slot details

- Discrepancies between fab drawing and Gerber files

- Undefined board construction

- Missing surface finish details

- Drill file not provided

- One-to-one scaling is not done on the Gerber files

- The drill file is not in ASCII format

- Holes are missing

- Layer stack-up information is missing

- Plated and non-plated holes are not distinctively defined

- The aperture list is missing

- Plane layers without thermal connections

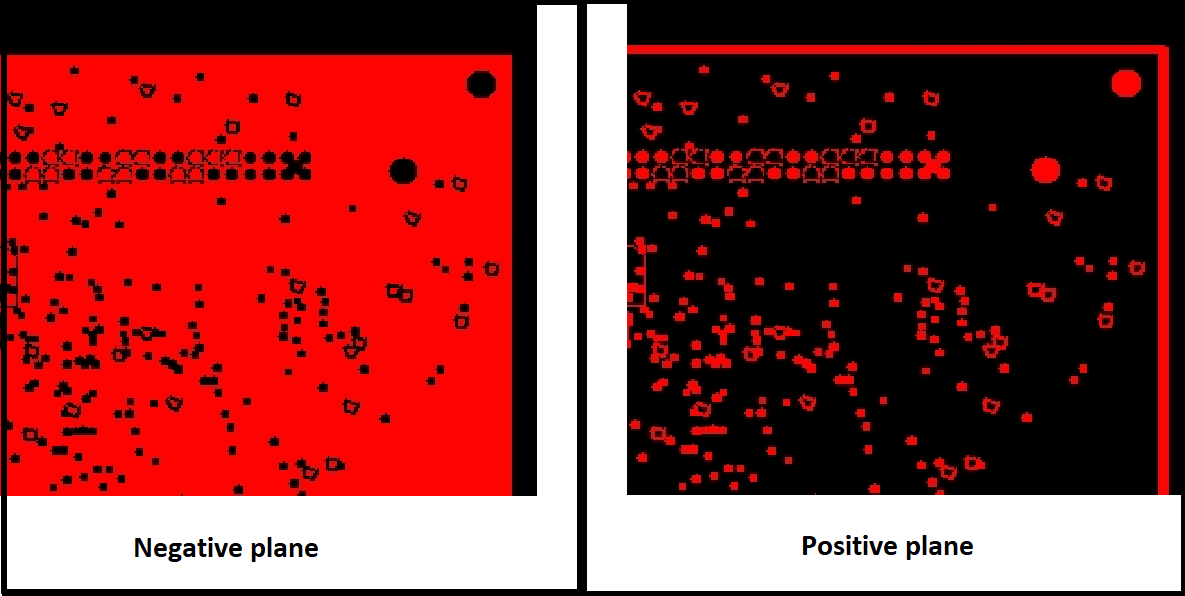

All plane layers should be submitted in a negative format (plane layers). A negative plane includes the data that comprises elements like thermals, anti-pads, splits, etc. Whereas, the data in a positive plane layer will show copper features. Negative plane layers have the following benefits over positive plane layers:

-

- Reduces the file size

- Quicker to analyze

- Reduces testing time

- Polygons should not be present in the plane layer/signal layer, as the CAD program may miss filling these areas resulting in poor board functionality.

- To reduce delay, it is recommended to provide the IPC netlist be for the boards that require electrical testing.

All the facts mentioned above provide a general idea about what should be included and the things that are usually missed out while requesting a circuit board quote. Small negligence will eventually become the reason for a production delay. Therefore, the more accurate the quote, the faster the board fabrication.

If you have any queries related to PCB quote, please let us know in the comments section below.